Municipality of Genoa has recently approved a project for the restoration of some manhole covers in the historic city center, replacing the existing siphons with the innovative ECOSYSTEM

The image above is more eloquent than many explanations and highlights how many mosquitoes and larvae are present in the same well, in the same period, before and after the ECOSYSTEM installation.

It goes without saying that ECOSYSTEM preserves the sewer pits, which are essential for the management of roads and sewers, by closing the manhole and preventing mosquitoes from laying their eggs, at the same time blocking rats and cockroaches, helping to reduce the release of bad odors and radon gas.

For more details watch the following videos: https://youtu.be/tiT8s4CEYeQ and https://youtube.com/shorts/azHR70kLx0w?feature=share

We are pleased to announce the acquisition of the majority of Schiavetti Enzo S.r.l. which became part of the Fratelli Cosulich Group

The presence of Enzo Schiavetti remains in the new corporate structure, as partner and CEO.

The entry into the Group is aimed at creating a synergy capable of consolidating the presence of the two complementary companies in the market.

This acquisition will enrich the already broad offering of Link Industries, active in thermo-acoustic insulation products, in building ranges, and more generally of the entire Maritime, Building & Industrial Supply unit, which was recently established in the Group, witnessing continuous growth in the diversification of its activities.

For more information we report the complete press

#LaForzadelGruppo

Paving an outdoor space is a useful choice for enhancing the property and usually requires a simple survey of the area and a minimum preliminary project, having a wide choice of materials available.

However, it is important to maintain a sort of aesthetic continuity that accompanies the external areas, for this reason filling seals are used to guarantee continuity of materials.

For more information read the following article

In all situations of facing buildings, respecting distances and in coherence with the context, the use of urban greenery can become, if well planned, an important tool for mitigating spaces, transforming into real urban furniture integrated into the surrounding environment.

In fact, greenery within cities not only performs the very important ecological-environmental function by attenuating the effects of buildings and regulating the microclimate, but also has a great aesthetic and architectural value that embellishes the corners of cities and reduces critical points.

For more information read the following article.

It is increasingly evident that urbanization processes significantly reduce the infiltration capacity of city soil during rainfall events. This inevitably results in the migration of various substances from the place where they are deposited to the entrance into the drainage system: a phenomenon known as wash off.

For more information read the following article

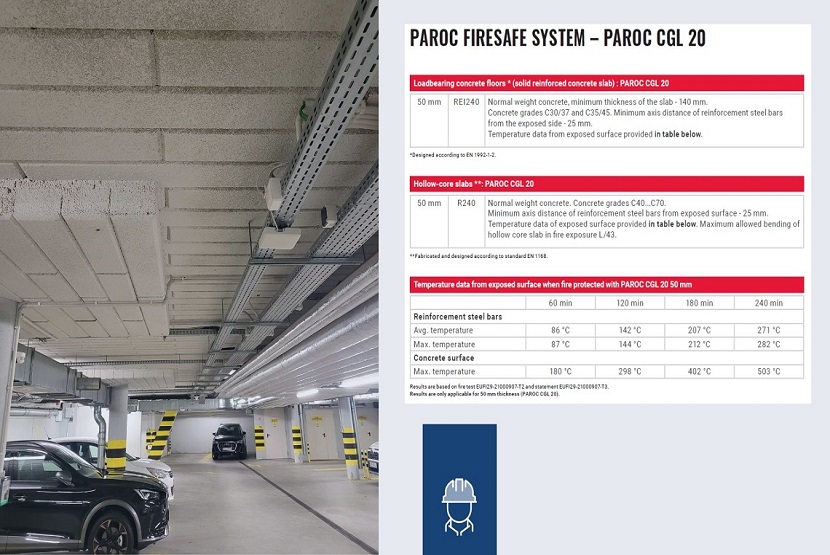

In order to answer to the question how could be reduced the energy consumption and promote environmental comfort with containing application costs in the cold floors, the answer is simple: PAROC© CGL - it improves energy efficiency, significantly reduces the energy needed for heating and cooling, reduces unwanted noise and maintains the room temperature at the desired level in a single application.

For more information read the following article

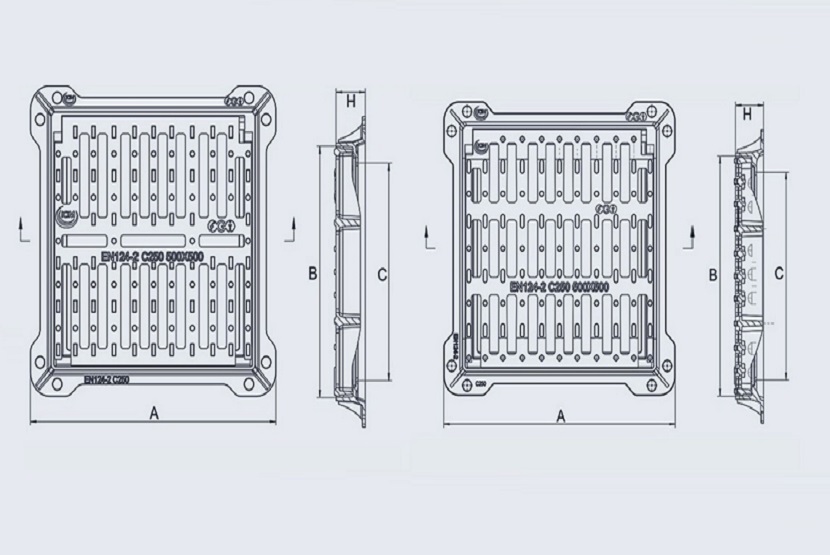

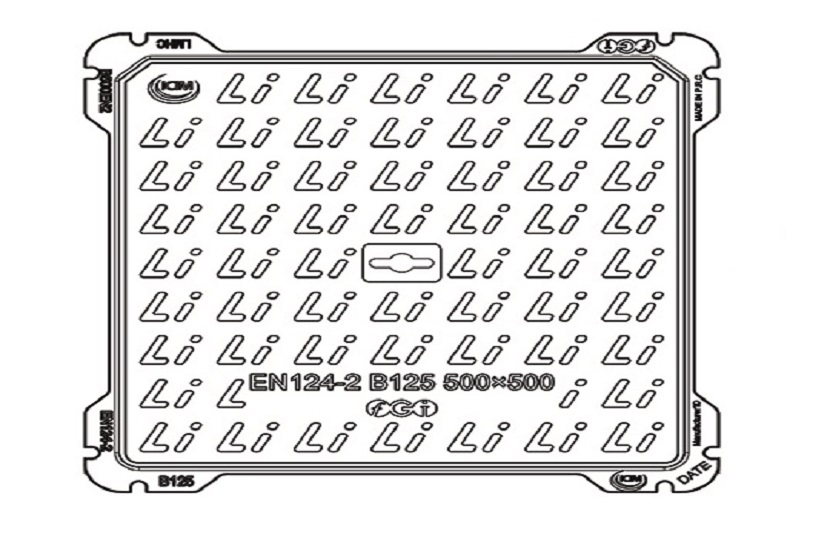

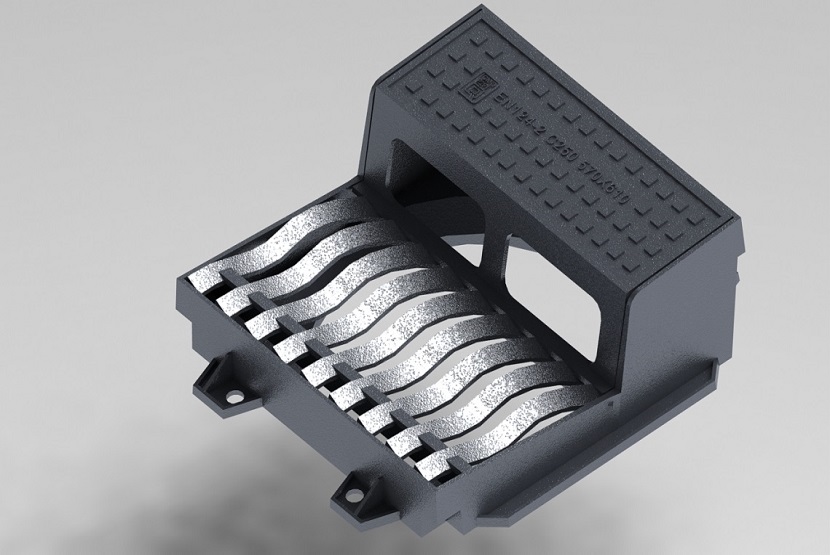

Among the elements that make up the urban drainage system there are crowning and closing devices. The UNI EN 124:2015 standard defines:

• crowning device the upper part of a collection well composed of a frame and grate with or without cover;

• closing device the upper part of an inspection pit or inspection chamber composed of a frame and a cover and/or grid.

In this case, the gully gratings play the fundamental role of connecting the road surface and the sewer pipes, intercepting the rainwater that flows on the surface, but also that of closing manholes serving the electricity, telephone and road lines.

Based on their hydraulic role, the gully gratings are designed to significantly interfere with the rainwater runoff regime, counteract road erosion and avoid dynamic and viscous aquaplaning linked to the thickness of the water film on the roadway.

For more information read the following article

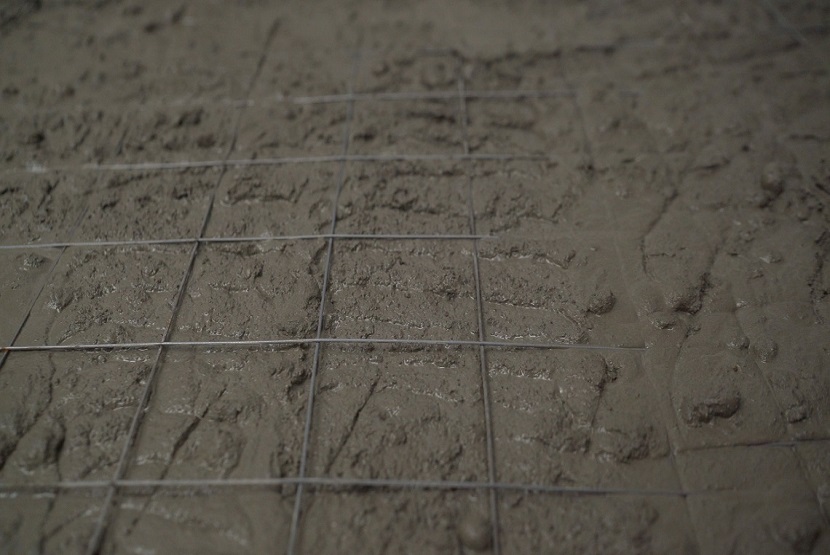

The structure of a building flooris is a result of an elaborate stratigraphy that depending on the material chosen and the type of floor on which it is laid.

The use of the terms subfloor, laying base and reinforced mesh as synonyms often misleads, because they are different parts of the stratigraphy.

In usual building practice, the subfloor is laid on top of the attic: a horizontal layer, approximately 10 cm thick, having the function of filling the cavity with the systems and compensating for thickness irregularities.

The reinforced mesh is subsequently laid as a support layer for the floors which has the purpose of resisting the various mechanical stresses imparted both by the flooring and by its operation, distributing the static and dynamic loads.

It is one of the components of the stratigraphy of the floor that must be studied with greater attention based on the type of floor and the physical and mechanical performance required, which is why it is said: "each floor has its own reinforced mesh".

For more information read the following article.

According to the new Whistleblowing provisions, to guarantee the anonymity of the whistleblower, institutions are required to establish adequately managed reporting channels whose personal data and documentation relating to reports must comply with the rules and principles established by the General Protection Regulation of Data (GDPR).

For this reason, a dedicated online platform has been activated in Link that meets the defined requirements, and the person responsible for managing the internal reporting channel will be the Ethics Committee of the subsidiaries of the Cosulich Group of which Link Industries S.p.A. is part.

For further information you will find at your disposal, in theuseful documents on the company website:

Procedura Whistleblowing (P18)

Codice Etico _ rev 3

For further information do not hesitate to contact us.

Asphalt is a mixture of solid and semi-fluid hydrocarbons which is used to create the surface layers of road paving. It is mixed and placed hot on the surface of the road to make the road level safe and homogeneous.

The term "asphalt" is used incorrectly because the correct term is artificial bituminous conglomerate.

Instead, for operations on small surfaces, is used "cold asphalt"

For more information read the following article

There are many ways to fence a property and vary according to the type of material and style chosen

Link offers a lightweight fencing system.

For more information read the following article

From 11 to 13 October – ACCADUEO 2023

the international biennial event which has been the reference point for the water sector at a national and international level for over 30 years.

An innovative exhibition proposal that highlights the synergy between the different sectors, where visitors will be able to discover the best practices in the energy and water fields, clarifying the orientations of institutions and national and European politics.

Where institutions, companies, experts, professional associations and training bodies will discuss issues relating to prevention policies, environmental sustainability, technological innovation in the energy and water fields, in the wake of the energy transition.

We will be pleased to meet you in Hall 25, Stand A1

The thermal insulation is a thermal insulation intervention, and in some cases also acoustic, in which a set of insulating layers are applied to the walls of the building to increase its energy efficiency.

Before starting work it is important to carry out various pre-intervention assessments

For more information read the following brochure

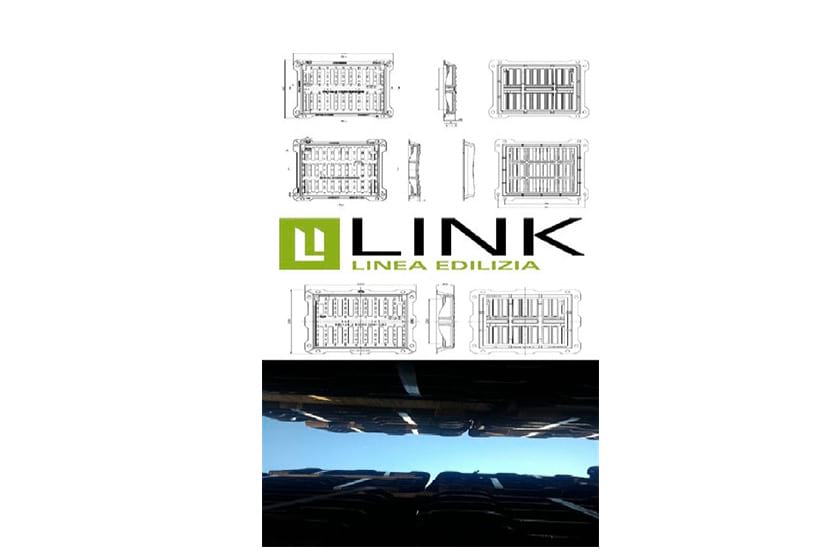

The cover/grid system, frame and well form a single body used for specific functions which will have to withstand stresses and be accessible for inspections and maintenance. The installation of the frame on the well is therefore an operation of fundamental importance to guarantee the stability of the device.

Before proceeding with the installation, it is therefore essential to take into consideration both the materials used and the project, as well as the minimum time to be respected before restoring normal circulation to prevent premature subsidence of the bedding, with the consequent separation of the frame from the cockpit.

For more information read the following article.

As per EU regulation 2020/1149, it is announced that starting from 24 August 2023, it will be necessary, for all professional and industrial users of polyurethane adhesives and sealing products, to have participated and achieved with positive results training courses concerning the handling of diisocyanates.

As per EU regulation 2020/1149, it is announced that starting from 24 August 2023, it will be necessary, for all professional and industrial users of polyurethane adhesives and sealing products, to have participated and achieved with positive results training courses concerning the handling of diisocyanates.

In Particular, the restrictions provided for in Annex XVII (restriction No. 74) of EU Regulation 1907/2006 (REACH) affect the use for industrial and professional use of articles and mixtures containing diisocyanates in quantities ≥0.1%, in polyurethane (PU) products.

It is therefore necessary that employers or self-employed workers guarantee industrial or professional users, who may have to handle the products mentioned above, the possibility of following appropriate training courses before their use.

The successful achievement of the training courses involves the issuance of an NCO license that will be valid for 5 years.

It is possible to carry out the courses at accredited institutes, occupational safety consultants, trade associations, or through the training platform made available by FEICA (Association of the European adhesives and sealants industry) in collaboration with other polyurethane manufacturers, available in various EU languages and with free use, accessible at this link: www.safeusediisocyanates.eu .

Employers must ensure that their employees have successfully completed training on the safe use of diisocyanates, prior to the use of the substance or mixture itself. The training must take into account the specificity of the products supplied, composition, packaging and conditions of application and storage

Diisocyanate’s suppliers must ensure that recipients receive sufficient information to enable their employees to conduct courses in the official languages of the Member State(s) and provide any list of products/mixtures sold to them which may contain diisocyanates in quantities ≥0.1%.

Manufacturers of articles containing quantities of diisocyanates exceeding 0.1% are obliged to notify their customers.

For this purpose, please note that at the following link: https://echa.europa.eu/documents/10162/503ac424-3bcb-137b-9247-09e41eb6dd5a are provided restriction number 74 (Diisocyanates) in Annex XVII of the REACH Regulation 1907/2006.

Please note: since diisocyanates are classified as respiratory and skin sensitisers of category 1, exposure by the skin or by inhalation of these substances can cause occupational diseases such as asthma.

Currently products containing diisocyanatesthe (such as chemical compounds used in the production of polyurethane compounds) marketed by Link Industries are:

• Emfimastic PU40FC

• Emfimastic PU403

• Emfimastic PU50

It is also recommended that:

• the indication of the presence of these substances is reported on the product’s safety data sheet;

• the safety data sheets report in section 2.2 the indication of the presence of diisocyanates, their range of concentration in percentage and the reference to EU regulation 2020/1149;

• details of the CAS number of the substance subject to restriction 74 are also given in section 15;

• the prevention measures and the use of adequate protection systems for handling the product are also reported in the safety data sheet.

Our technical department remains at your disposal for any further clarifications.

Access to a work area subject to the movement of loads and the transit of heavy vehicles requires the utmost attention of all operators.

For details see the following link

Thank you

The Link team

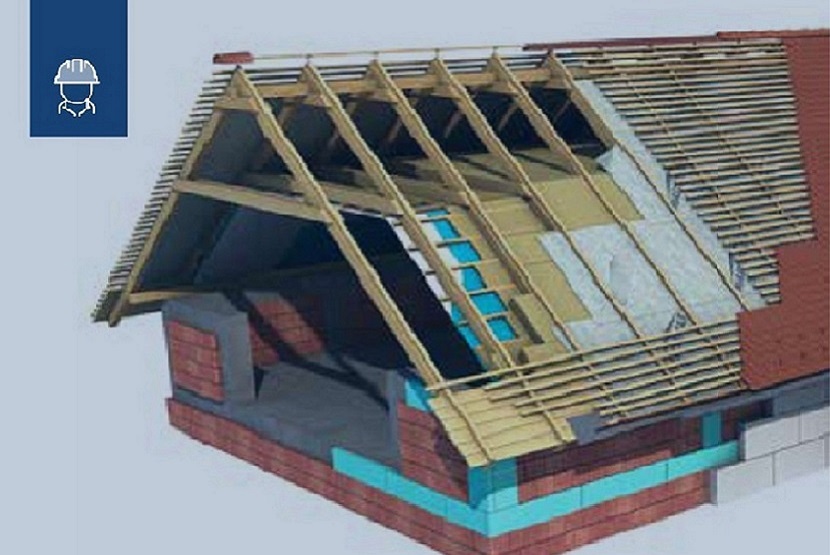

The cold and damp "old attic" and the torrid under roof which served as a deposit and intermediate element to safeguard the underlying living spaces, are now superseded by welcoming and functional attics thanks to an elaborate stratigraphy of specific materials which, if well designed, interact to create comfort and energy savings.

For more information read the following article

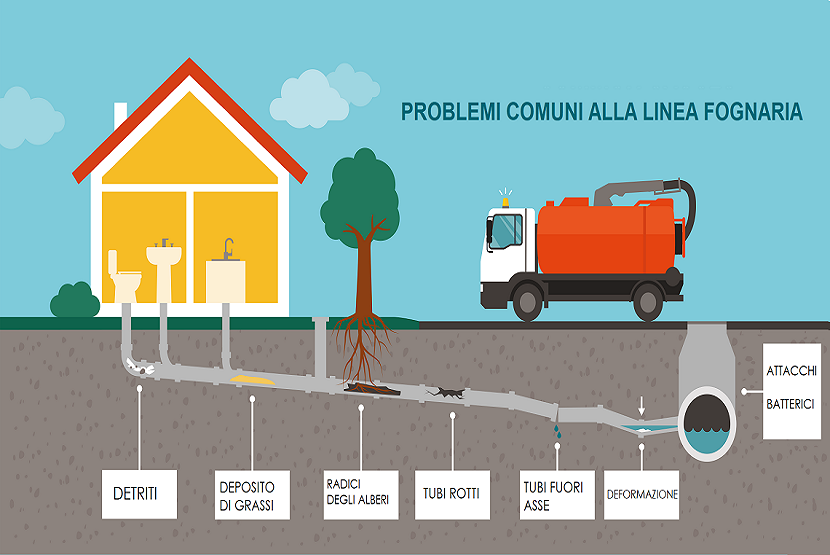

In the coming decades the cities will increasingly take on the character of a vast area, with the consequent increase in the built environment, the structural network, land use and the reduction of permeable and transpiring surfaces.

The city sewage infrastructure has to deal with problems that concern not only the outdoors (the capacity of deep and superficial infiltration, the volume of discharges, the management of green spaces, environmental pollution, etc.) but also indoors, due to those phenomena that the operators define as "the attacks of nature".

For more information read the following article

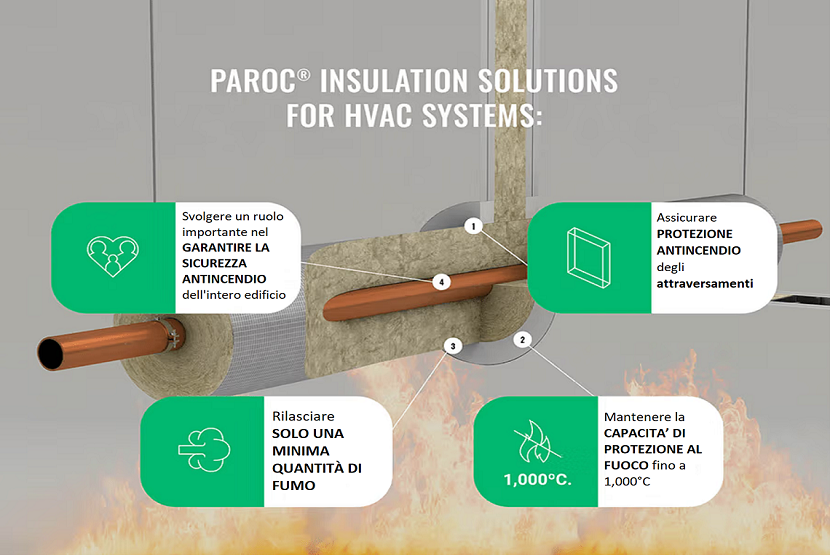

HVAC is the acronym for "Heating, Ventilation & Air Conditioning" referring to the complex of technologies, systems and equipment that are based on the design, development and supply of hardware and software components with a high level of connectivity to contain energy consumption and increase, as a whole, the efficiency and well-being of the internal environment.

The choice of building materials with adequate fire resistance is essential in the realization of the various systems and, from a sustainability perspective, can largely provide its contribution.

For more information read the following article

As Alfonso Morone wrote: "scattered by the thousands in every city, almost indestructible, difficult to improve, often with decades (or even centuries) behind them" manhole covers are one of the most widespread products, but also among the least valued in the national infrastructure, offering their constant contribution in the blue infrastructure chain.

We propose the following article published on Edilportale

The new provisions on environmental labeling require that at the end of use the packaging must be correctly disposed of and the indications for the correct management of the waste must be indicated on the label.

Environmental labeling therefore identifies all packaging placed on the Italian market, indicates its composition, facilitates its collection, reuse, recovery, recycling and correct disposal by the consumer. From 1 January 2023 it is therefore necessary to report, in a visible and easy to understand way, the type of each material and the corresponding alphanumeric code used in the packaging of products intended for both B2B and B2C trade on the label.

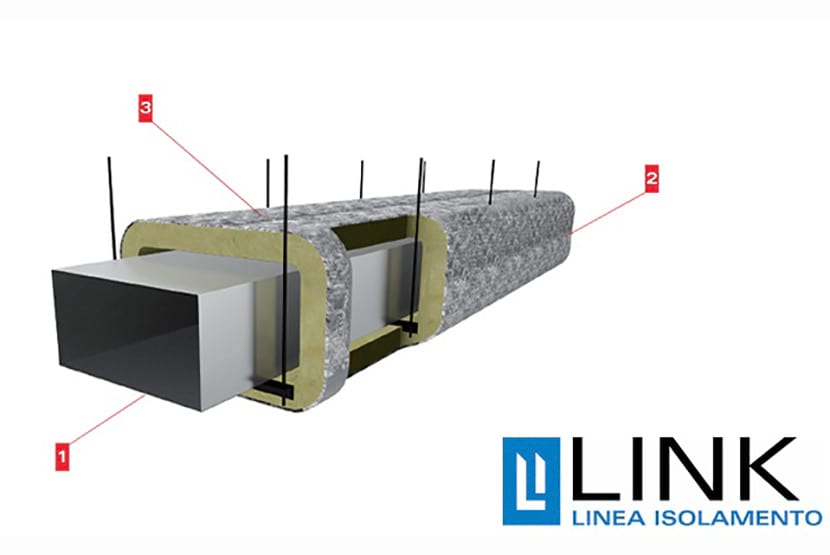

PAROC Hvac Fire BlackCoat is the new Paroc solution suitable for fire protection of horizontal and vertical, rectangular and circular ventilation and air conditioning ducts.

The slab or mat solution was developed to prevent the spread of fire from the duct to the room or from the room to the duct. It combines unique properties in terms of fire protection with a discreet and elegant aesthetic finish, as the rock wool mats and slab are covered with a black lacquered reinforced aluminum sheet.

For more information read the following article

The European Chemicals Agency (ECHA) deals with matters related to EU legislation on chemicals. Based on the premise that better knowledge and regulation of harmful chemicals protects workers, consumers and the environment, facilitates product recycling and encourages industry to develop safer alternatives. ECHA assists companies in complying with the legislation, promotes the safe use of chemicals, provides information on chemicals and addresses substances of concern.

Substances likely to have serious effects on human health and the environment can be included among substances of very high concern: named SVHC (Substance of Very High Concern) on which legal obligations incumbent

Link offers a series of high-performance and safe wheelbarrow wheels because they comply with the SVHC standard.

For more information read the following article.

Wishing you a Merry Christmas and a Happy New Year,

we take this opportunity to remind our operations during the Christmas period:

the Spinetta Marengo (AL) warehouse will be closed from 23/12/2022 to 08/01/2023;

the Genoa offices will be closed from 02/01/2023 to 08/01/2023;

the salesmen are at your disposal, reachable via the usual email or mobile contacts.

Happy Holidays!

The Link Team

The manhole cover is one of the most popular products, but also one of the least valued, while boasting a role within the complex dynamics of urban transformations following the industrial revolution and the relationship with the design culture.

The article proposed by Sole24Ore of last November 6 starts from an extremely captivating sentence by the Italian designer Roberto Mango: "The man who walks with his eyes fixed on the stars could miss the stars that are at his feet" which guides the reader among the artifacts that are under the eyes (and feet) of all without receiving the right attention.

We therefore propose the following reading from Sole24Ore

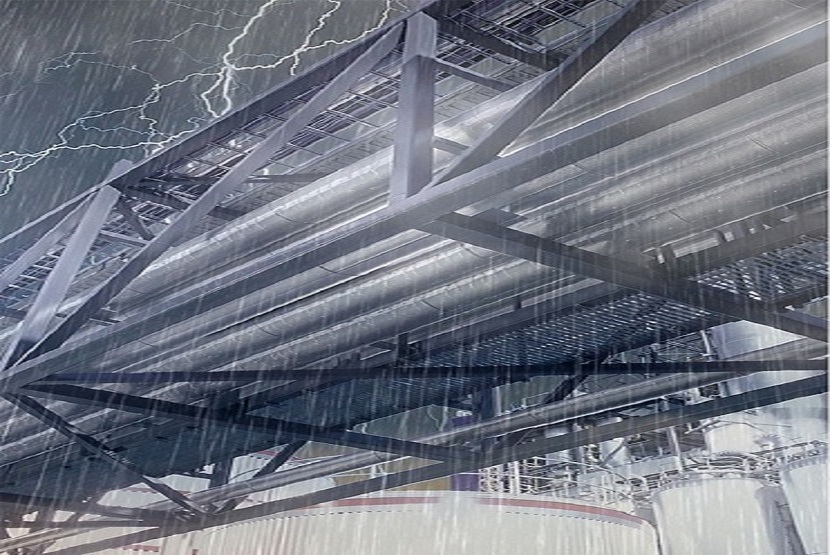

Paroc Clad System is weatherproof, UV-resistant, salt-water resistant and impermeable to water. It can withstand temperatures up to 680°C making it good for protecting against temperature losses on high-temperature systems and steam lines. This makes the insulation system suitable for a wide range of cases including power, oil and gas, chemical manufacturing, the food industry and coastal applications.

For more information read the following article

Galvanizing is the process by which a zinc coating is applied to a metal product, generally made of steel, in order to protect it from corrosion.

The galvanizing process can take place through different methodologies. Among the most used is hot dip galvanizing: an anticorrosive treatment that occurs by immersing the products in a bath of molten zinc, at about 450 ° C, after a series of pre-treatments.

For more information read the following article

Combined kerb and drainage units are fundamental elements of connection between the roadway and rainwater sewer pipes, designed to intercept and convey the rainwater (or road washing) that flows in the surface. They are installed on the roads, in correspondence with the sidewalk kerbs of streets, squares or parking lots, to prevent water from excessively accumulating on the surface, exposed to the meteoric event. In addition to this thanks to hinged covers, they allow cleaning and an easier access to underground rain collecting systems.

For more information read the following article.

Chambers are very important in the rainwater management, in fact they stand as a fundamental part of the system. Moreover, the drain trap is an essential element of the gully/chamber system by conveying rainweater correctly, preventing bad smells coming out from the drains, avoiding in the same time clogging and whirpools. In most of the market available drain traps , however, rainwater and debris often create stagnation, becoming an environment issue for the proliferation of unpleasant insects such as tiger mosquitoes, cockroaches, drain flies, and several other insects and rodents, creating a real hygiene issue. These problems are often addressed with insecticides and chemicals that may accumulate, from time to time, in the aquifers and in the surrounding soils with a relapse toxicity problem to the environment.

As a possible solution against insect larvae, with particular focus on sustainability, Link proposes the innovative ECOSYSTEM: an intelligent tilting lever (open/close) mechanism.

For more information read the following article

The industrial insulation details generally provide that the insulation of the pipes takes place during downtime for maintenance, when the temperature of the pipes is low, and then changes rapidly when the system returns to operation, creating an important thermal expansion that can lead to to severe losses of heat and energy. Therefore, a double layer insulation system is often required to mitigate the potential opening of the joints.

Expert in such processes, Paroc offers half-shell cup solutions and, in addition, the innovative PAROC Pro Lock single-layer solution.

PAROC Pro Lock is a unique solution, which offers the advantages of double-layer insulation but with a single single-layer application. It is a single cup with 2 overlapping thicknesses and staggered interlocking joints (Z-Lock) - both circumferential and longitudinal - which minimize the heat loss caused by mechanical expansion.

For more information watch the video!

The pannel for concrete floor and the substrate are two different layers present in the floors, as a horizontal structure that divides the different floors of a building. The intrados surface of the floor is called the ceiling, while the extrados surface is the support of the floor of the upper floor. The floor system rests on the extradosal surface, as a set of layers between the structural support and the final flooring: a system that requires careful planning to ensure resistance, stability and safety.

For more information read the following article!

PAROC and the characteristic red and white striped packaging, includes solutions for thermal, fire and acoustic insulation in several applications.

It is recognizable not only for its packaging but above all as a synonym for highly energy-efficient and fire-fighting insulation solutions.

Paroc products do not contain ingredients or chemicals that prevent their recycling, increase the comfort and safety of the environment in which they are installed, improve workplaces and the efficiency of industrial processes.

Paroc stone wool fully complies with the stringent dictates imposed by the Finnish RTS Building Information Foundation system for the classification of emissions of building materials, and also meets the most stringent requirements (M1) in the Finnish voluntary system for the calculation of emissions of insulating material.

For more information read the following article

Urban and peri-urban locations are characterized by partially waterproofed areas due to extensive overbuilding. Although generally equipped with infrastructures dedicated to the collection, confinement and treatment of rainwater and runoff, these areas constitute very complex environments due to urban development and the strong increase in vehicular traffic.

The increased contamination of run-off water and the relative worsening of the qualitative characteristics of the receiving water bodies have now become one of the cornerstones of environmental protection policies and, more generally, of the quality of life in urbanized areas.

For more information read the following article

Energy is the engine of contemporary society, and is now the subject of major transformations towards decarbonisation and sustainable development, and greater integration of renewable energies into energy systems: energy transition measures that affect not only businesses but also individuals, the environment and the world we live in.

The increase in the price of energy also generates inevitable repercussions on consumers, making it clear how great the advantages of a correct energy balance are. Therefore, the primary interest of each investor, business or private, is to increasingly ensure that their investment is functional, efficient and, of course, advantageous.

PAROC, a leading company in the insulation sector and synonymous with highly energy efficient and fireproof insulation solutions in rock wool, offers 3 winning keys for insulation:

• acoustic insulation of the ventilation channels with PAROC Hvac Slab

• thermal insulation of the pipes with PAROC Hvac Section Alucoat T

• fire protection of the concrete floor with PAROC CGL 20cy

For more information read the following article.

Wishing you a Merry Christmas and a Happy New Year,

we take this opportunity to remind you of our operations during the Christmas and New Year's celebrations:

Link warehouse at Spinetta Marengo and Genoa headoffice will be closed from 12/24/2021 (13.00 hrs) till 01/09/2022.

Our commercial officials, should you wish to contact them, can be reached via the usual email or mobile contacts.

Happy Holidays!

The appropriate classes of manhole covers and/or gully tops are distinguished according to the place of installation, the loading classes and are divided into groups. This classification, indicated in the UNI EN 124-1 standard of 2015, chapter 4, determines their use and place of installation, dividing them into groups numbered from 1 to 6. The Standard dictates (data in brackets) the minimum loading class of reference for each individual group. According to EN124-2015, manhole covers and/or gully tops must comply with certain parameters relating to the production material, whether or not combined with different materials, as well as meet precise design requirements.

For more information, read the following article

The specific characteristics of the process industry plants (such as the temperature of the stored material which can vary significantly between the various sections, the movement caused by thermal expansion and vibrations from the equipment connected to them) often produce humidity which, if not correctly resolved, it can drastically reduce the life of pipes and equipment, increasing the risk of leaks, greatly reducing safety.

For more information read the following article

In Bologna, from 6 to 8 October, will start the international water exhibition of technologies, treatments, distribution and sustainability www.accadueo.com

Link will be there!

Come and visit us at P A V / P A D 2 0 - S T A N D B 4 7

Contact us for tickets by sending an email to segreteria@linkindustries.com

#quilink

Fiberglass nets, often used in construction as a reinforcing structure for masonry, in particular for external insulation systems and wall leveling, but also to consolidate secondary elements such as floors and floors. They are a material with high mechanical resistance that does not rust, is not attackable by biological agents, has no aging or deterioration problems.

Thanks to the good performance of the fiberglass mesh and its results, it is evident how an efficient renovation of the masonry is today a high-performance choice that guarantees indoor comfort, duration of the investment and an increase in the real life of the structures at a low environmental impact.

For more information read the following article

The building roof has the function of preserving the internal environment from external agents, resisting the elements, preventing the onset of humidity and containing the building's heat loss. To obtain these performances, modern roofs have adopted a complex stratigraphy: the various layers interact with each other to perform the different functions required by the roof.

For more information read the following article

In physics the wheelbarrow is a second type lever which, consisting of a rigid body (lever) capable of rotating around a fixed point, fulcrum, (the axis of the wheel) does not carry energy, but moves towards an external position forces. In the second type lever, the transfer of energy is always advantageous because the power arm (the force we apply to lift the handles) is always longer than the resistance arm (the force we have to overcome - the load). It follows that the transport of a load through this type of lever is useful for those who have to carry weights.

Structurally, the wheelbarrows are formed by a container that receives the load, resting on a frame made of sheet metal, equipped with pedestals to support the wheelbarrow without it overturning and two handles, as an extension of the poles connected to the wheel axis. The poles form the frame of the wheelbarrow, and the supports for ground support are fixed on them.

Link offers a series of accessories studied to complete the building range, including wheelbarrow wheels, performing and safe because tested not only at the manufacturer, but also by national laboratories, designed to give completeness to the building range.

For more information read the following article!

The mechanical and thermal actions are generated in the industry plants often produce moisture which, if not properly resolved, can drastically reduce the life of pipes and equipment, increasing the risk of leaks, greatly reducing their safety.

An insidious aspect, increasingly recognized by professionals in the industrial sector, is the so-called CUI - Corrosion Under Insulation - as a severe form of localized corrosion that occurs mainly under the insulating material applied on steel equipment.

PAROC solutions for the process industry offer long-lasting, maintenance-free and energy-efficient products

For more information read the following article

Manhole tops are used to close service shafts, water and sewers systems as well as electric, telephone and other services' lines. Similarly, the gully tops, instead of the lid, adopt a grid and are mainly used for the collection of rainwater.

The manhole tops and gully tops characteristics and performances are regulated by the UNI EN 124: 2015 standard. Although presently adopted in all EU countries this Standard is not yet harmonized since it has never been published on the EU Official Journal.

For more information read the following article

When planning a sustainable building, the main challenge is how to achieve eco-friendly goals while ensuring a safe and well-functioning structure. In terms of energy, efficiency, it is not a question of how much insulation to add, but what is the right application choice for the building, considering both the entire ecosystem-building and its function as a system, to achieve full owner satisfaction and occupants.

For more information click here!

When planning a sustainable building, the main challenge is how to achieve eco-friendly goals while ensuring a safe and well-functioning structure. In terms of energy, efficiency, it is not a question of how much insulation to add, but what is the right application choice for the building, considering both the entire ecosystem-building and its function as a system, to achieve full owner satisfaction and occupants.

Thinking in terms of design through the lens of integrated systems (so that the acoustic, thermal and humidity mitigation systems work fully and efficiently throughout the life of a building), which takes into account the physical interfaces between the facade and the the building structure, as well as the functional structure between the envelope and the systems, represents a salient point in eco-friendly design. The regulatory framework, in this context, has changed over the years, paying particular attention not only to the aspects of energy containment of buildings, but also to those related to acoustic well-being, sustainability and safety (with particular attention to the danger of propagation of fire).

The trend in recent years to build ever taller buildings has brought the increased fire risk to the building system to the attention of researchers. In fact, architects and designers of curtain walls have often recognized that the void created between the attic and the external wall, if left unprotected, would allow fire and smoke to spread quickly from one floor to another.

Firespan 40 & 90 EU panels offer a solution to this problem as they have been tested to the North American standard ASTM E2307: a fire test standard for evaluating the performance of perimeter fire barrier systems that measures the capability of perimeter fire barrier systems prevent the spread of fire when the outer wall flexes or deforms during exposure to fire. ASTM E2307 also determines the period of time in which the perimeter fire protection system limits the penetration of the flame through the cavity (internal void between the floor and the external wall.)

Firespan 40 & 90 EU are Underwriters Laboratories certified fire resistant panels, moisture resistant, which guarantees anti-corrosion and anti-mold effect, moreover they do not deteriorate over time, maintaining constant performance of thermal insulation, fire protection, better acoustic comfort and vapor barrier with the foil faced Firespan 40 & 90 or used in steel back pan assemblies. The panels comply with the North American standards ASTM C 612 and UL specific for mineral fiber panels.

Firespan 40 & 90 EU possess the certifications necessary for the buildings to obtain the LEED and are scrupulously examined at each stage of the life cycle in order to calculate their environmental impact

All related information is collected and published in technical documents and certificates called EPD (Environmental Product Declaration) in accordance with the EN 15804 standard.

For further information please do not hesitate to contact us!

Urban spaces have experienced a great transformation in history following the historical and cultural changes of man, immediately perceptible in the architecture and plans of our cities.

Structural changes that have brought out the difficulty of calibrating this evolution with the needs of the community and its territorial identity, such as to trigger, in the architectural debate of the 21st century, strategies for recovering data spaces, putting hand to new "hooked" architectural elements to existing buildings. The search for new design solutions has led to architectural experiments such as parasitic architecture designed to transform urban space by taking something from existing buildings and inserting new elements.

Whether it is a question of hanging green spaces or urban en plein air constructions, galvanized grids and recessed access cover can offer their contribution in ectoparasitic architectural creations.

For more information read the following article

Kemppi Oy and its distributor Link Industries have been longstanding partners developing Kemppi brand awareness and distribution within the Italian market for the past ten years. Kemppi and Link Industries have now agreed to set up a new business model in this second biggest arc welding market in Europe. The parties have signed a contract which aims at, as of January 1st 2021, establishing a new company Kemppi Italy which will continue and further develop the Kemppi product sales and distribution, earlier conducted by Link Industries in Italy.

“Kemppi is looking at Italy as a potential high growth market, regarding the market share. With the new organisation and business model, we are positive that we´re able to continue our growth and reach excellent long-term results despite the global challenges and radical changes” says Hannu Jokela, Vice President, Markets, Kemppi OY

“I am very satisfied with the agreement reached with Kemppi. It will ensure continuity in the business management both for Kemppi customers and all other parties involved. It has been the main driver of the deal from the Link perspective” comments Marta Cosulich, President, Link Industries

Mikko Jauhiainen has been appointed as Managing Director, Kemppi Italy S.r.l. as of January 1st 2021. He has been earlier responsible for the distributor sales in Southern Europe, including the Italian market, at Kemppi and has a long experience in working with Link Industries and its professional team of welding experts.

“Close cooperation with its partners and end users is in the core of Kemppi business and this transaction brings us one step closer to our Italian dealers and customers.” says Mikko Jauhiainen, Managing Director, Kemppi Italy S.r.l. “New business model will strengthen Kemppi’s position in Italy, which is one of the most important European markets for us. I am very confident that this agreement will provide great business opportunities for all Kemppi partners in Italy and the ability to further develop their Kemppi business activities,” he continues.

For more information: Mikko Jauhiainen Mikko.Jauhiainen@kemppi.com

The decision to install a fence has several practical reasons: to improve privacy, to establish boundaries clearly, to separate two sectors, to allow pets to roam freely without going outside and, for example, to protect the garden or gardens of wildlife. Usually the motivation that leads to the choice of a fence determines its type.

For more information read the following article: The Link fencing nets system

Link offers its customers a professional felt, non-slip, absorbent, reusable cloth, hot coupled with PE film, 180g / m (PFR-110/125/150), as an important precaution to protect the surfaces of the house from any fragments stains and frequent passages with work shoes during renovations

For more information click here

Renovating the house is a necessary process in the life of a property that is inevitably destined to age. The interventions can take place both on the building part and on the systems and can concern important redevelopment actions or simply be planned for a restyling of the interior of the house.

Beyond the extraordinary or ordinary maintenance interventions, even the simple decision to renovate the house, starting with a new paint job, requires targeted planning and the implementation of some precautions. In fact, painting is one of the simplest ways to bring aesthetic changes to the rooms of the house through an apparently simple operation that requires some precautions, such as: knowing the types of water-based paints, the characteristics of the surfaces, trying the chosen color, having the right amount (detergent, spatulas, sandpaper, putty, etc.) and protect the environment (floors, stupid, electrical sockets, baseboards and furniture).

The walls must be carefully prepared, brushed and often washed. If there are cracks and holes, it is necessary to scrape the damaged areas by removing the parts that tend to come off and fill the cracks. Similarly, in the event that there is upholstery to be removed, it is necessary to proceed with a deep wetting, or if there is mold, a specific treatment is essential. Works that involve a significant production of debris, powders and liquids that can compromise the success of the work.

For this reason, as a first precaution, it is essential to spread a specific cloth on the floor that protects it from fragments, from any stains and from frequent passages with work shoes.

Link Industries, offers its customers PFR-110/125/150: a professional, non-slip, absorbent, reusable cloth, hot coupled with PE film, 180g / sqm.

It is commonly called "Millefiori" for the colored dots of the recycled fabric that constitutes it, whose raw material is verified in accordance with the "REACH" regulation 1907/2006 / EC, to ensure constant monitoring of any risks of intrinsic chemical substances in the products marketed.

The application of a specific felt, instead of the common newspaper sheet or polyethylene sheets, offers a greater grip reducing the risk of slipping and, given the structure of the cloth coupled with the polyethylene film, holds liquids more easily avoiding the stains. The specific grammage performed protects the floors from accidental impacts, scratches and grooves due to the pressure of stairs or small scaffolding.

Correctly spread, up to covering the skirting board on which it can be fixed with relative paper tape for building works, it saves 1/4 of the time, minimizing the final phase of restoration and cleaning. It can also be used several times and used not only in building applications but also in removals as a packaging membrane, minimizing the investment.

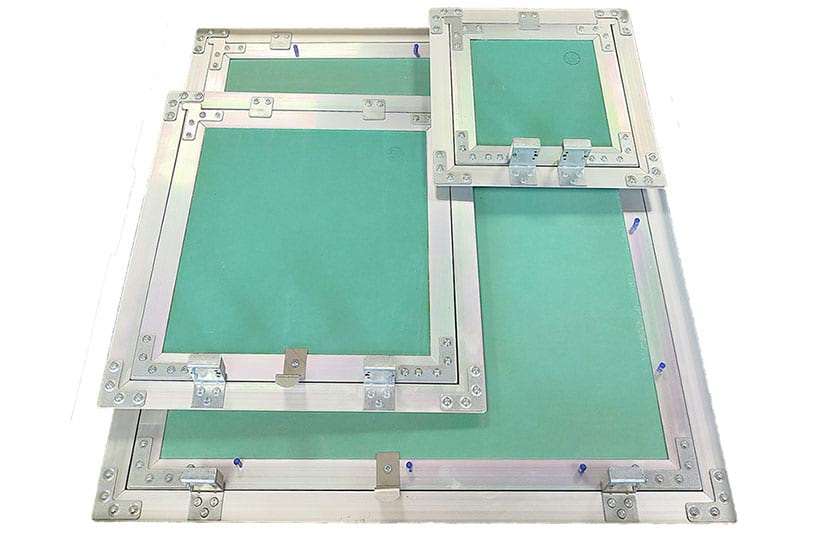

We offer two main ranges both consisting of an aluminum structure, raw finish, PUSH & PULL closure and moisture resistant plasterboard:

ECO RAW RANGE - Consisting of angular fixings with self-tapping screws and door lock with steel fin

ECO PLUS RAW RANGE - Consisting of rivet fasteners and door lock with chain and EVO gaskets.

Link hatches are easy to install and their assembly usually involves 4 phases:

1) marking INTERNAL CONTOUR and engraving the shape and size of the hatch on the plasterboard panel

2) insertion of the hatch in the hole made in the plasterboard to position the external frame

3) fixing the hatch frame using suitable plasterboard screws

4) hatch door installation and closing

None hesitate to contact us!

Quality, innovation, safety and lightness solutions: these are just some of the values that characterize the world of sailing and that Link Industries searches every day in its work.

Inspired by these ideas we are proud to support, with our partner Paroc, Tommaso Cilli and Bruno Mantero at the 420 Italian Sailing Championship and on the occasion of the 420 Gold Cup.

Public green spaces in cities as well as in new urban settlements have undergone a great transformation over times, following the historical-cultural, architectural, landscaping, regulatory and environmental changes of urbanization, always closely linked to the ability to reconcile buildings and nature.

Whether it is residential or private, public, historical or special green, a structural analysis of acclimatization is always necessary, consistent with the environmental characteristics, for a careful architectural, landscaping and environmental design.

Link is pleased to offer designers its gully tops and manhole tops for vehicular and pedestrian areas made of GJS 500-7 spheroidal cast iron, coated with bituminous alkyd paint subjected to SVHC analysis (Substances of Very High Concern), regularly and rigorously carried out by SGS

For more information click here

A salient feature of mesh for fencing yard site is to focus attention on safety in a sector of activity which by its nature exposes workers to particularly high risks.

For more attention read the following article.

Insulating materials can significantly increase the ability of a building to withstand a fire, consequently the choice of the correct insulator can affect the general safety of a building.

For more information read the following article.

In a moment that imposes unimaginable challenges until a few weeks ago, we at Link are working hard to ensure the service we always have, even if our operations are conditioned by the necessary measures to combat COVID-19.

The Link offices operate on home working shifts and the Spinetta Marengo (AL) warehouse, based on the Decree of 10 April u.s., will operate a few days a week, except for new regulatory developments.

We want to be ready for the restart!

Do not hesitate to contact us for any information

The Link team

Link is there!

Team Link is compact in facing the Covid19 emergency by continuing to guarantee the best service in respect of the health and safety of our customers, suppliers, cooperators and colleagues.

How? Thanks to smart working, training activities through sharing platforms and our warehouse keeping up with the prevention guidelines.

United in this difficult moment towards a better future.

The manhole tops are structures with a removable cover used on services, drain and sewer to grant access and inspection to underground chambers. To the same extent, the gullies are similar assemblies in this case with slotted tops, designed to receive water for discharge into the drainage systems.

Link manhole tops and gullies designs, provide an efficient securing feature called "Smartlock". The elastic properties typical of ductile cast iron, applied onto lock bars, allow the securing of the tops to the relative frames avoiding accidental or unauthorized openings and in the same time greatly reducing clatter. Smartlock is available on all C250 and D400 manhole tops and Gullies.

For more information click here

The panels for concrete floor underlayments, once correctly applied,

are an optimal base for the flooring assemblation used to support the mechanical stresses imparted both by the flooring and by its exercise,

distributing the loads and giving the needed flatness for the application of the coating, thus reducing the eventual damages and consequent repairing costs.

For more information click here

How can the Process Industry contribute to reduce the negative climate impact - and at the same time save money? Fortunately, there is a simple solution to the problem: PAROC, focused on the characteristics of the industrial process, offer long-lasting, maintenance-free and energy-efficient solutions that can guarantee a specific industrial process with the lowest possible energy consumption, thus minimizing waste.

For more information read: PAROC solutions for insulation in the process industry

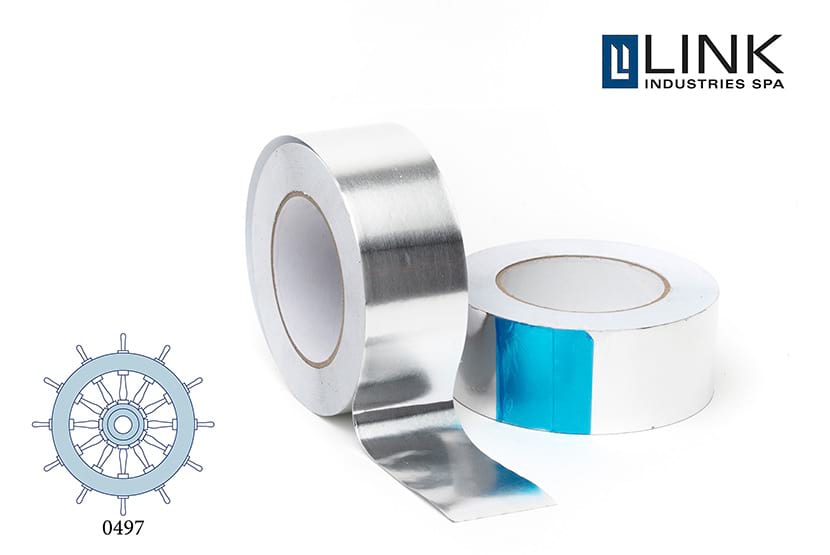

Thanks to the continuos research of our technical team, Link Alu Tape has obtained the marine equipment brand "Steering wheel" according to the Directive MED 2014/90 / UE.

Thanks to the continuos research of our technical team, Link Alu Tape has obtained the marine equipment brand "Steering wheel" according to the Directive MED 2014/90 / UE.

LINK ALU TAPE is a tape with smooth baked aluminum film in thickness 26 μm with high self-adhesive power. It is generally used for joints and other forms of protection in industrial, hvac and marine insulation. The tape has been rigorously tested by a third-party certifying body and has successfully passed the verifications thus obtaining the certification of "Low flame spread” for marine application.

By certifying its products (tapes for joints, glue, sealants) Link aims to:

- improve maritime safety;

- improve the protection of the maritime environment;

- facilitate the free exchange of marine equipment within the European Union and at the same time maintain a common level of security.

For more information read: Link Alu tape with 'timoncino' logo

Link presents PAROC Calculus on the market: an innovative and sophisticated software proposed by Paroc for the calculation of technical insulation. Calculus is an easy-to-use program suitable even for those who are not familiar with this type of software, that offers the possibility of creating your own database and saving the calculations of the entire project through two versions: on-line on the portal and a downloadable version one on the own pc with more features.

Link presents PAROC Calculus on the market: an innovative and sophisticated software proposed by Paroc for the calculation of technical insulation. Calculus is an easy-to-use program suitable even for those who are not familiar with this type of software, that offers the possibility of creating your own database and saving the calculations of the entire project through two versions: on-line on the portal and a downloadable version one on the own pc with more features.

The software calculates the solutions realized obtained with PAROC technical insulation products based on equations described in standard EN ISO 12241, which provides the methods for counting the properties related to the heat transport of building and industrial installations, mainly in steady state, providing a simplified approach to the treatment of thermal bridges. Furthermore, the latest developments of the program open the door to the world of shipbuilding: the database of available products has been updated by introducing the PAROC Marine & Offshore range, including all the relevant specialized coatings dedicated to them. This update allows to perform the calculations related to all the isolated insulated elements present on ships and offshore installations - such as drains, pipes, ducts, tanks - by correctly using the MED-certified PAROC products.

To perform calculations with Marine & Offshore products, just access the software link, place a check mark in the "Marine object" selection box under the "Select object" item. The offer of the product database goes on to naval ones.

tick the "Marine object" box under the "Select objet" heading. The product offering will be switched to marine products.

The introduction of Marine & Offshore products with specific coatings allows the correct thermal emissivity to be used in calculating the surface temperature of the insulation. This represents a considerable importance both for the protection of the embarked personnel, guaranteeing the effective safety of the material used, and for the guarantee of the correct functioning of the insulation applied. In fact modern shipbuilding increasingly pays attention on the issue of weight saving of boats for reasons of fuel efficiency, navigation autonomy and maneuverability. Moreover, a useful software, always updated and correctly configured on applied products by the parent company , is an indispensable tool for designers in order to assess the weight of the insulation used.

Calculus is free and easy to use with any device.

So all you have to do is try it and tell us your opinion!

Road freight transport is governed by various laws that govern the transit, times, documentation and safety. Among these, Annex III of the Ministerial Decree of 19 May 2017, establishes the principles relating to the fixing and control of the load and indicates what are the rules for the regulation of anchoring devices goods on road vehicles. The regulation of the operations of transfer and fixation of products on vehicles is determined to protect the subjects engaged not only in the movement of the loads but also the driver, other road users, pedestrians, the vehicle and the content itself transported.

For more information: Securing load on road transport

The stone wool insulation is a natural product, used for over 80 years, obtained from molten volcanic rock, transformed in fibers and impregnated with a little bit organic binder (2-4%) in order to stabilize it, then passed into another oven for hardening and cutting to size.

The Paroc stone wool thus obtained is extremely natural and has excellent characteristics of: Durability - Energy efficiency - Sound absorption - Fire protection - Anti humidity - Reuse and Safety.

Paroc stone wool is not only a natural product, but naturally sustainable because it follows a precise protocol with respect for the environment: an added value for the environmentally conscious consumer who respects the resources of our planet.

For more information follow the link: Paroc the naturally sustainable insulation

The form modeling activity, in foundry processes, represents one of the fundamental and most delicate steps in the cast iron product cycle, whose design and implementation requires specific skills and high levels of precision. It is the place where ideas become a shape; where the cast iron melted in the oven, collected in the ladle and transported in the pouring channel, reaches the mold in order to produce a carefully prepared form.

For more information read: The shape of ideas

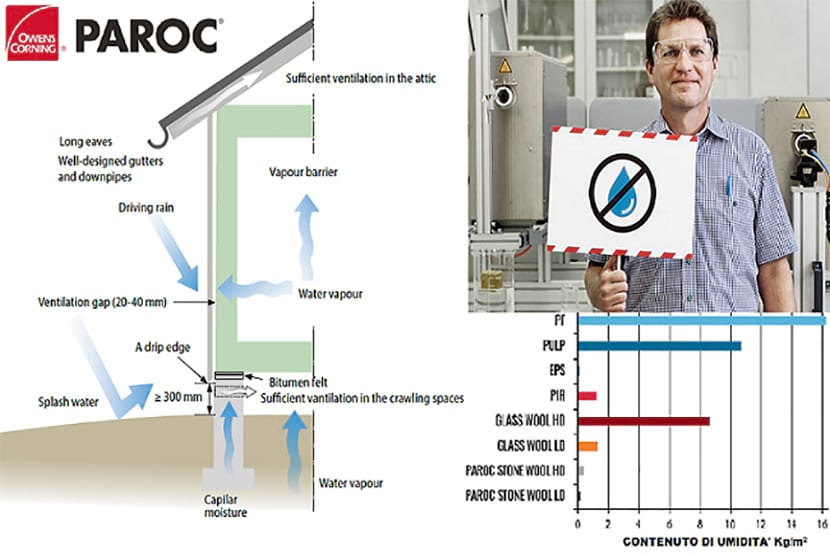

From an experimental study carried out on different insulating materials by an independent external laboratory, Paroc stone wool proved to be one of the most performing insulation materials in terms of moisture resistance. The analysis was carried out on four different mechanisms of moisture transport and their effect on buildings with the awareness that moisture penetrates the structures not only during atmospheric precipitation, but also through a silent path, difficult to control.

From an experimental study carried out on different insulating materials by an independent external laboratory, Paroc stone wool proved to be one of the most performing insulation materials in terms of moisture resistance. The analysis was carried out on four different mechanisms of moisture transport and their effect on buildings with the awareness that moisture penetrates the structures not only during atmospheric precipitation, but also through a silent path, difficult to control.

Moisture transport mechanisms are carefully studied in the building design phase, but they must also be carefully assessed during the construction of buildings, not only for the correct application of the products, but also for the interchanges between different materials and their conservation in the dockyard.

An independent study conducted by the VTT (VTT-S-05337-17) demonstrated that there are differences among the insulating materials in terms of moisture resistance.

In fact, during the construction of a building a certain amount of atmospheric water is inevitably given to the structure, in addition to the one contained in construction materials, and even if the insulation does not get wet, the humidity level of the rest of the components increases. For this reason, the water vapor permeability of the insulation materials plays a key role in the drying time of the entire structure, allowing moisture to escape.

For more information download the free Paroc Guide and follow the article on Edilportale: The driest insulation on the market

Frequently the atmospheric precipitations exceed the infiltration of water into the ground. In environments with non-waterproof surfaces such as woods and fields, the runoff phenomenon is poorly perceived because the meteorological waters are generally filtered into the ground. Instead, in urban environments, characterized by overbuilding, the surfaces are mostly impermeable and rainwater flows superficially in a motion often conditioned by depressions, pipes and channels. These runoff waters, if they are not managed correctly, can cause damage to the environment, because they are responsible for the leaching of particulates and heavy metals deposited on the asphalt. Devices for gully tops and manhole tops for vehicular and pedestrian areasand tanks for the drainage and containment of rainwater, wastewater or irrigation: these become the fundamental safeguards for the containment of this phenomenon.

For more information read: Link Industries: tank covers and access cover

Heat dispersion, energy inefficiency, constructive discontinuities, reduced living comfort are some aspects that are felt in thermal bridge areas.

These areas, if not properly designed, cause various problems:

For more information: Link Industries: le zone di ponte termico e l'involucro edilizio

The primary interest of each owner is that their investment is functional, efficient and advantageous. To obtain such a performance, plays a decisive role the performance of the building envelope that they must guarantee a wholesomeness of the indoor parts and the longevity of the systems.

For more information click here: Ristrutturare incrementando efficienza e funzionalità

The primary interest of each owner is that their investment is functional, efficient and advantageous. To obtain such a performance, plays a decisive role the performance of the building envelope that they must guarantee a wholesomeness of the indoor parts and the longevity of the systems. The technological evolution of the energy performance of the building envelope is expressed fully in the Passive House, whose energy demand for heating and cooling the internal environment is cleared of passive devices. An integral part of the passive architecture is the "Rendered facade", as a composite solution that provides for the application with gluing and / or mechanical fixing of insulating panels on the external side of the building envelope, finished superficially with a shaving cycle with reinforcement network. This solution, properly designed and correctly laid (both in new buildings and in renovations), becomes the main instrument to achieve correct thermal insulation by minimizing energy consumption, maximizing comfort, while increasing efficiency and durability of the system. investment and the real life of the structures with a low environmental impact.

Based on the European Standards (ETICS System), Paroc has developed a special panel, the LINIO 10, which meets the characteristics required for the single rock wool product for the cladding system and which meets all the requirements for the insulating panels contained in it. in the ETA (European Technical Assessment), obtained according to the ETAG004 Guidelines by the leading market systems.

To complete the passive insulation system of the building envelope, Link proposes glass fiber nets as reinforcing elements for the external glazing cycle of the cladding system, and for the insulating cover package it recommends a series of breathable and control membranes steamed for the correct migration of the water vapor flow from the inside to the outside of the building, also through the cover:

• nets fiber glass (reinforcing elements of the external shaving cycle of cladding systems) are a material that does not rust, is not attackable by biological agents, has no problems of aging or deterioration, and according to the type chosen, finds large use in buildings for reinforcement of the finishing shaving cycle in ETAG004 insulation systems, or as networks for thick plasters or nets for thin coatings of plasters.

• transpiring membranes (which provide a waterproof and airtight cover, resistant to loads) and vapor control barriers (which regulate the flow of steam that migrates from the inside to the outside of the heated building, avoiding thermohygrometric situations critiques with formation of interstitial or superficial condensation in the covering stratigraphy, especially in winter periods).

The proposed solutions can be used to reinterpret "old methods" in an innovative way, reaching, with extreme ease of installation, the highest performances, solving at the same time the problems related to the recovery of the existing and / or the efficiency of the new one.

The future is the Passive House, informed to increase the efficiency and functionality of your home through a new green and sustainable approach.

For more information click here: Ristrutturare incrementando efficienza e funzionalità

Modern construction can be defined not only by triumphs of contemporary architecture but also by ever-developing installation technologies. From heating and water pipes to smoke and exhaust pipes and chimneys, from HVAC equipment to ventilation ducts – installation systems perform many roles in terms of a building’s proper functionality; fire safety being one of the most important. Why should proper technical insulation be given priority when speaking about buildings’ passive fire protection?

For more information:

https://www.archiproducts.com/it/notizie/link-industries-e-una-questione-di-classe_66286

Designed for efficient air and water circulation for heating, ventilation and air conditioning purposes, HVAC systems often pass for a building’s “cardiovascular system”. Since it is common for pipework to cross through individual fire separation walls, it is crucial for them to retain sufficient fire protection. Because pipe penetrations weaken a partition’s overall resistance, professional fitting and proper materials are necessary in order to prevent/minimise fire transition through individual fire zones. Because of that all openings and service penetrations must meet certain requirements:

According to EN 1366-1 standard there are various types of ducts that differ in virtue of the propagation from inside or outside to the fire conduct (iào, ißo) and the vertical or horizontal arrangement of the pipeline ( I-I). When describing service penetrations’ fire resistance, we employ similar performance criteria as in the case of building components and construction, namely fire protection rating related to integrity (E) and insulation (I). Normally the fire resistance classification is given as a time limit (in minutes 15, 30, 45, 60, 90, 120, 180, 240 or 360) during which the performance criteria is fulfilled in a standardised fire test. Integrity (E) is the ability of a test specimen of a building construction element to prevent the flames and hot gases from passing through when exposed to fire on one side, and to prevent the occurrence of flames on the unexposed side. Insulation (I) defines said object’s ability to restrict the temperature rise of the unexposed face to below specified levels. Construction meets its integrity limit after ignition of a cotton wool pad or sustained 10 seconds’ flaming on the unexposed side. The limit for fire protection rating related to insulation (I) is met when the temperature increase on the unexposed side exceeds 180°C in relation to the initial state. The analogy between performance criteria between barrier walls and service penetrations is no coincidence. The latter, being part of fire separation walls, should be classified with fire protection classes (EI) required for said constructions, meaning a necessity to employ insulation materials with fire reaction class not lower than the fire resistance of the construction itself. Fume seal (S) defines the passage of flue gas to the side not exposed to fire.

Depending on the installation type, different insulation methods and materials should be applied and ventilation ducts must be selected with the appropriate fire-fighting performance. Paroc has developed a non-combustible wired mat usually covered with aluminum foil interposed between the wool and the net for fire protection of the ventilation ducts. The product is PAROC Hvac Fire Mat (Alucoat), a fireproof, flexible mattress made of biosoluble rock wool, covered with aluminum foil on one side and then quilted with a triple-twist hexagonal galvanized steel mesh. It is tested to achieve a protection up to EI 120 of rectangular and circular ducts, both vertical and horizontal, for internal and external fire exposure. For all the solutions, the product thicknesses to be applied and the characteristics of the metal pipelines will have to respond to what reported in the laboratory certificates.

At the time of installation it is required to cover the ventilation duct with the PAROC Hvac Fire Mat Alucoat mat and to close the longitudinal and transverse edges with galvanized steel wire. Fix the mat further to the ventilation duct with the galvanized steel wire every 330 mm (two fastenings per mattress band).

For more information:

https://www.archiproducts.com/it/notizie/link-industries-e-una-questione-di-classe_66286

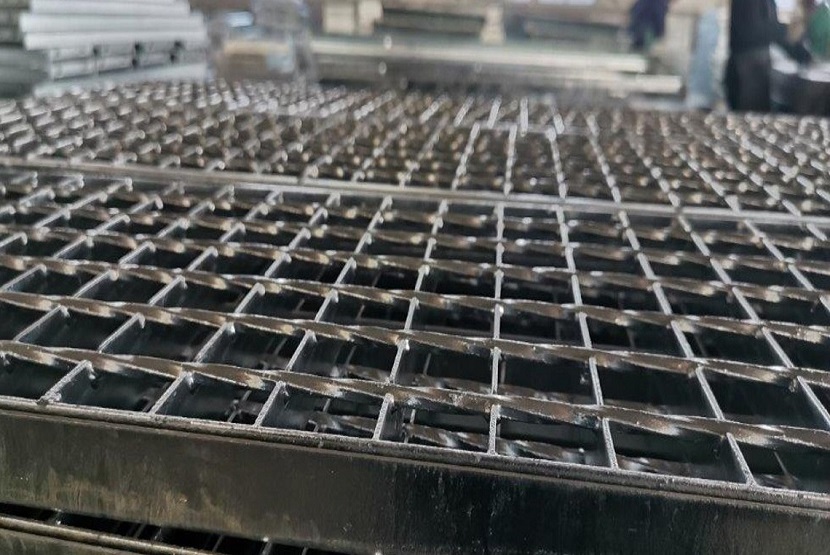

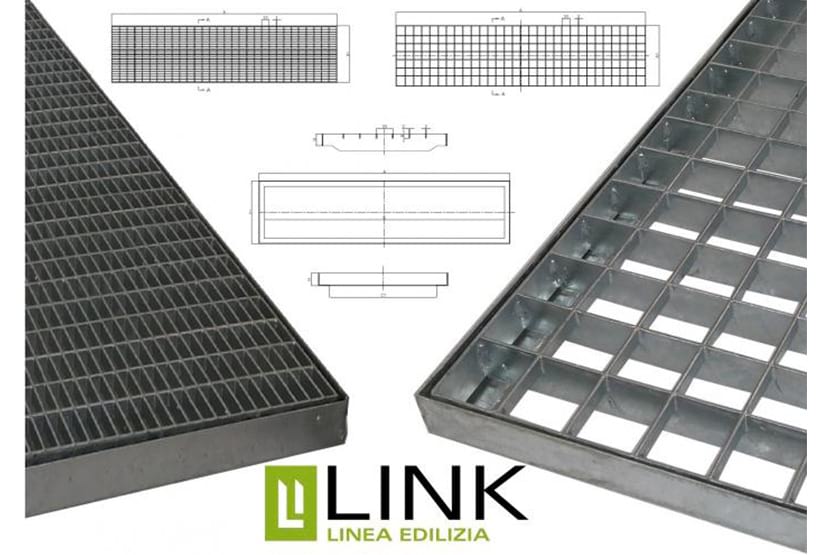

The grid is a rectilinear group consisting of two plates contained by a border that is distinguished in:

• the supporting plate is the one with the largest dimension suitable for unloading weight on the edging;

• the connecting plate (or secondary) is the one that connects and unites the load-bearing plates, unloading the weight on them and making them solid.

The grid can be contained in a frame for the intended use, whose function is to interpose between the grid and the product on which it will be supported.

The different production process distinguishes the grids in three types:

• electro-welded - smooth and twisted connecting rounds sold welded to the bearings .;

• pressed - the connecting plates are interlocked by means of special grooves arranged mechanically by very high pressure;

• printed - the supporting plate, with a closed profile, is formed by punching a pre-galvanized steel sheet obtained through the cutting processes.

Link, thanks to its long experience in the sector, is able to develop a wide range of customizations, while a series of steel grids, pressed (with or without frame), hot-dip galvanized according to the UNI EN standard are always available in stock ISO 1461, standard mesh (33x33 mm) and light duty heel proof (33x11 mm) as a selection proposed by our technicians.

The range of sizes available, the various possibilities for customization, durability and a marked aesthetic taste make these products widely used in various applications. For more information please contact us.

Read also: LINK Industries: la griglia su misura

In the world the availability of water is enormous, but only about 3% is represented by fresh water (ground and surface water) whose withdrawals increase progressively. In fact, the theme of a correct and efficient management of the water resource becomes a recurrent topic and in several sector studies: we can read that water is now considered a precious and increasingly "scarce" good. In the analysis of the asset-water, the reasoning on the water infrastructure that supports it and the consequent need for its efficiency, is fully part of it. The urban drainage system, made up as follows, consists of a complex network of pipes, mostly underground, installed to collect and dispose, away from civil and production settlements, rainwater or surface runoff and wastewater.

The meteoric runoff, cooling waters deriving from industrial activities, those for irrigation from gardens, parks and spring waters, are considered as white water. They flow into the sewers through urban drainage systems that intercept them while they flow, channeling them into the plumbing drainage system.

Link offers its customers a series of concave and flat grids, in cast iron, designed to collect and flow these waters. They are structured for the use of siphon, equipped with an innovative safety system with snap closure and compliant with EN124-1 / 2: 2015.

GSGEN grids:

- Group 3 - Class C250 starting from size 300x300 up to 700x700

- Group 4 - Class D400 starting from size 500x500 up to 700x700

Our drains have a system of constraint to the frame that uses rotation hinges, allowing the opening and, if necessary, the possible removal of the grids. They are also provided with elastic closing bars: a safety system that prevents accidental opening while allowing regular access for cleaning and maintenance of the collection facilities.

Our drains in class C250, in compliance with the Decree of the Ministry of Public Works, have loopholes with a width of less than mm. 20 for the safety of cycling traffic. The draining surface has been developed to be largely within the regulatory requirements and to favor the normal flow of water.

For more information: Link Industries presents the GSGEN grids

Le Pipe Sections Paroc are on Infobuild news

The stakeholder’s primary interest is to ensure a functional, efficient and, of course, beneficial investment. With this aim, Link presents PAROC Pipe Sections, the suitable product to increase the efficiency and lifetime of industrial plants as well as to achieve a proper thermal insulation of high-temperature pipes or pipes for sanitary water heating, and to minimize energy consumption by maximizing the real life of the plant.

PAROC stone wool is a natural and environmentally friendly material that offers highly performing solutions for thermal, acoustic insulation and passive fire protection in civil engineering and upgrading, industrial plants, naval and off- shore.

In addition, the research and development activities in the industrial insulation has received advantage from close cooperation with customers and industry experts. All products are designed to increase the efficiency and functionality of the plant and to meet the strictest quality standards.

Therefore, we would like to introduce you, through the related product and video-related cards, the above-mentioned Pipe Sections:

Generally stone wool solutions and particularly PAROC Pipe Sections increase the comfort and safety of the environments in which they are used, improving the energy efficiency of buildings and yield performance of the plants: the advantages are of great economic value and environment resulting from a well-insulated system.

New tests for fire protection of steel and concrete with PAROC CGL20cy and PAROC FPS 17.

PAROC has developed two specific products for protection of concrete (PAROC CGL20cy and PAROC FPS 17) and steel (PAROC FPS 17) exploiting the excellent thermal-acoustic and fire protection properties of stone wool.

Concrete - PAROC CGL20cy protects until REI 240 with only 60mm of insulation on whatever type of concrete slab

Concrete and steel - PAROC FPS17 protects until REI 240 with only 20mm of insulation on whatever type of concrete slab and until R 210 whatever type of steal beams and pillars with several thicknesses.

For more information, send a email at isolamento@linkindustries.com

Link introduces the new non-vapour permeable underlay on: Edilportale e Archiproduct

Link Industries Spa strongly believe in high quality products accompanied by relevant certifications as a main value for our customers.

Therefore the range of accessories for marine insulation offered by Link is covered by following certifications:

Module B - Low flame spread M.E.D. Certification according to IMO Res. Msc. 61(67) FTP Code Annex 1 p 2 and 5

Module E (EC quality System Certificate).

Link Industries Spa strongly believe in high quality products accompanied by relevant certifications as a main value for our customers.

Therefore the range of accessories for marine insulation offered by Link is covered by following certifications:

Module B - Low flame spread M.E.D. Certification according to IMO Res. Msc. 61(67) FTP Code Annex 1 p 2 and 5

Module E (EC quality System Certificate).

LINK GLASS FABRIC TAPE 0.12

White glass fabric strip 105 gr/m2 and 0.12mm with special self-extinguish resins to make it soft, permeable to glue and weavelock.

It is particularly indicated in marine application to cover joints between mineral wool slabs covered with glass fabric coating.

LINK GLUE V20

white flame retardant vinyl adhesive for marine application particularly indicated to bind glass fiber strips on joints between mineral wool slabs covered with glass coating.

For further information our technical department is at your constant disposal.

It is also used for gluing coatings (such as glass cloths) to insulating materials such as mineral wools (stone or glass wool)

LINK PE WRAP

Incombustible stone wool slab PAROC Marine Slab wrapped in a polyethylen self extinguish black film.

It is mainly used in marine application for the insulation of floor inside cabins.

For further information our technical department is at your constant disposal.

Sede Amministrativa: Ponte Morosini, 49 Marina Porto Antico 16126 Genova

ITALIA

Tel. +39 010 2546.901 – Fax +39 010 2546.999 –

Sede Logistica: Strada della Guasca, Zona Industriale D5 15122 Spinetta Marengo ITALIA

Tel. +39 0131 216.556 – Fax +39 0131 611.447

Cookie Policy