In order to answer to the question how could be reduced the energy consumption and promote environmental comfort with containing application costs in the cold floors, the answer is simple: PAROC© CGL - it improves energy efficiency, significantly reduces the energy needed for heating and cooling, reduces unwanted noise and maintains the room temperature at the desired level in a single application.

For more information read the following article

As per EU regulation 2020/1149, it is announced that starting from 24 August 2023, it will be necessary, for all professional and industrial users of polyurethane adhesives and sealing products, to have participated and achieved with positive results training courses concerning the handling of diisocyanates.

As per EU regulation 2020/1149, it is announced that starting from 24 August 2023, it will be necessary, for all professional and industrial users of polyurethane adhesives and sealing products, to have participated and achieved with positive results training courses concerning the handling of diisocyanates.

In Particular, the restrictions provided for in Annex XVII (restriction No. 74) of EU Regulation 1907/2006 (REACH) affect the use for industrial and professional use of articles and mixtures containing diisocyanates in quantities ≥0.1%, in polyurethane (PU) products.

It is therefore necessary that employers or self-employed workers guarantee industrial or professional users, who may have to handle the products mentioned above, the possibility of following appropriate training courses before their use.

The successful achievement of the training courses involves the issuance of an NCO license that will be valid for 5 years.

It is possible to carry out the courses at accredited institutes, occupational safety consultants, trade associations, or through the training platform made available by FEICA (Association of the European adhesives and sealants industry) in collaboration with other polyurethane manufacturers, available in various EU languages and with free use, accessible at this link: www.safeusediisocyanates.eu .

Employers must ensure that their employees have successfully completed training on the safe use of diisocyanates, prior to the use of the substance or mixture itself. The training must take into account the specificity of the products supplied, composition, packaging and conditions of application and storage

Diisocyanate’s suppliers must ensure that recipients receive sufficient information to enable their employees to conduct courses in the official languages of the Member State(s) and provide any list of products/mixtures sold to them which may contain diisocyanates in quantities ≥0.1%.

Manufacturers of articles containing quantities of diisocyanates exceeding 0.1% are obliged to notify their customers.

For this purpose, please note that at the following link: https://echa.europa.eu/documents/10162/503ac424-3bcb-137b-9247-09e41eb6dd5a are provided restriction number 74 (Diisocyanates) in Annex XVII of the REACH Regulation 1907/2006.

Please note: since diisocyanates are classified as respiratory and skin sensitisers of category 1, exposure by the skin or by inhalation of these substances can cause occupational diseases such as asthma.

Currently products containing diisocyanatesthe (such as chemical compounds used in the production of polyurethane compounds) marketed by Link Industries are:

• Emfimastic PU40FC

• Emfimastic PU403

• Emfimastic PU50

It is also recommended that:

• the indication of the presence of these substances is reported on the product’s safety data sheet;

• the safety data sheets report in section 2.2 the indication of the presence of diisocyanates, their range of concentration in percentage and the reference to EU regulation 2020/1149;

• details of the CAS number of the substance subject to restriction 74 are also given in section 15;

• the prevention measures and the use of adequate protection systems for handling the product are also reported in the safety data sheet.

Our technical department remains at your disposal for any further clarifications.

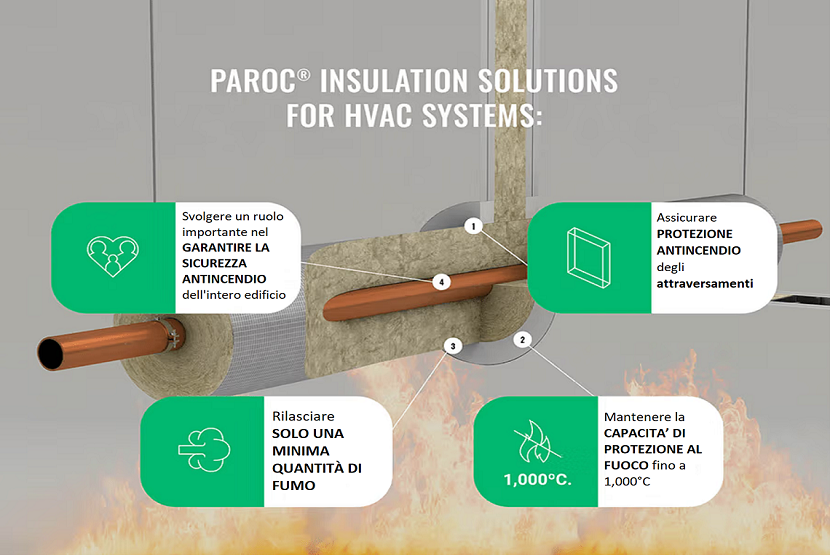

HVAC is the acronym for "Heating, Ventilation & Air Conditioning" referring to the complex of technologies, systems and equipment that are based on the design, development and supply of hardware and software components with a high level of connectivity to contain energy consumption and increase, as a whole, the efficiency and well-being of the internal environment.

The choice of building materials with adequate fire resistance is essential in the realization of the various systems and, from a sustainability perspective, can largely provide its contribution.

For more information read the following article

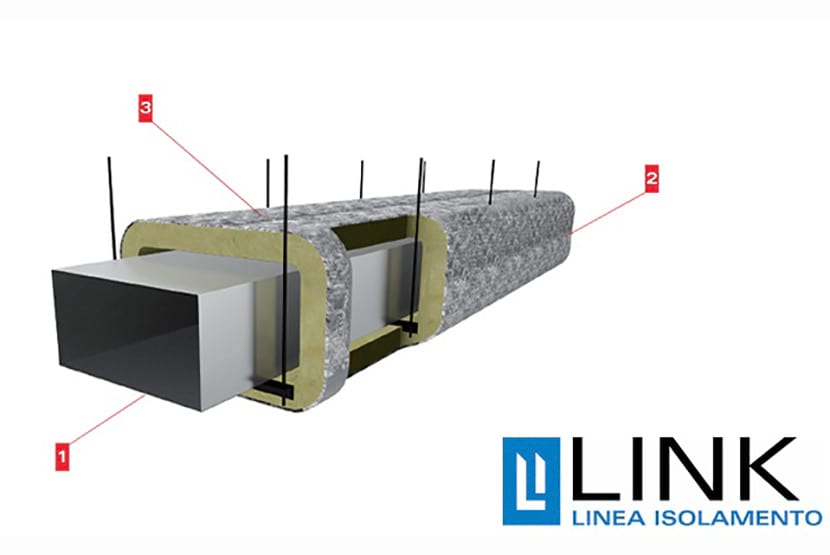

PAROC Hvac Fire BlackCoat is the new Paroc solution suitable for fire protection of horizontal and vertical, rectangular and circular ventilation and air conditioning ducts.

The slab or mat solution was developed to prevent the spread of fire from the duct to the room or from the room to the duct. It combines unique properties in terms of fire protection with a discreet and elegant aesthetic finish, as the rock wool mats and slab are covered with a black lacquered reinforced aluminum sheet.

For more information read the following article

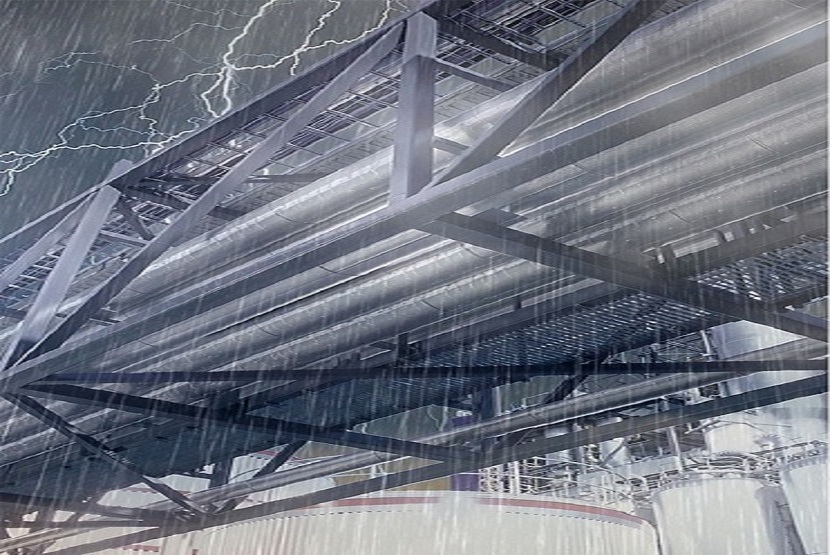

Paroc Clad System is weatherproof, UV-resistant, salt-water resistant and impermeable to water. It can withstand temperatures up to 680°C making it good for protecting against temperature losses on high-temperature systems and steam lines. This makes the insulation system suitable for a wide range of cases including power, oil and gas, chemical manufacturing, the food industry and coastal applications.

For more information read the following article

The industrial insulation details generally provide that the insulation of the pipes takes place during downtime for maintenance, when the temperature of the pipes is low, and then changes rapidly when the system returns to operation, creating an important thermal expansion that can lead to to severe losses of heat and energy. Therefore, a double layer insulation system is often required to mitigate the potential opening of the joints.

Expert in such processes, Paroc offers half-shell cup solutions and, in addition, the innovative PAROC Pro Lock single-layer solution.

PAROC Pro Lock is a unique solution, which offers the advantages of double-layer insulation but with a single single-layer application. It is a single cup with 2 overlapping thicknesses and staggered interlocking joints (Z-Lock) - both circumferential and longitudinal - which minimize the heat loss caused by mechanical expansion.

For more information watch the video!

PAROC and the characteristic red and white striped packaging, includes solutions for thermal, fire and acoustic insulation in several applications.

It is recognizable not only for its packaging but above all as a synonym for highly energy-efficient and fire-fighting insulation solutions.

Paroc products do not contain ingredients or chemicals that prevent their recycling, increase the comfort and safety of the environment in which they are installed, improve workplaces and the efficiency of industrial processes.

Paroc stone wool fully complies with the stringent dictates imposed by the Finnish RTS Building Information Foundation system for the classification of emissions of building materials, and also meets the most stringent requirements (M1) in the Finnish voluntary system for the calculation of emissions of insulating material.

For more information read the following article

Energy is the engine of contemporary society, and is now the subject of major transformations towards decarbonisation and sustainable development, and greater integration of renewable energies into energy systems: energy transition measures that affect not only businesses but also individuals, the environment and the world we live in.

The increase in the price of energy also generates inevitable repercussions on consumers, making it clear how great the advantages of a correct energy balance are. Therefore, the primary interest of each investor, business or private, is to increasingly ensure that their investment is functional, efficient and, of course, advantageous.

PAROC, a leading company in the insulation sector and synonymous with highly energy efficient and fireproof insulation solutions in rock wool, offers 3 winning keys for insulation:

• acoustic insulation of the ventilation channels with PAROC Hvac Slab

• thermal insulation of the pipes with PAROC Hvac Section Alucoat T

• fire protection of the concrete floor with PAROC CGL 20cy

For more information read the following article.

The specific characteristics of the process industry plants (such as the temperature of the stored material which can vary significantly between the various sections, the movement caused by thermal expansion and vibrations from the equipment connected to them) often produce humidity which, if not correctly resolved, it can drastically reduce the life of pipes and equipment, increasing the risk of leaks, greatly reducing safety.

For more information read the following article

The mechanical and thermal actions are generated in the industry plants often produce moisture which, if not properly resolved, can drastically reduce the life of pipes and equipment, increasing the risk of leaks, greatly reducing their safety.

An insidious aspect, increasingly recognized by professionals in the industrial sector, is the so-called CUI - Corrosion Under Insulation - as a severe form of localized corrosion that occurs mainly under the insulating material applied on steel equipment.

PAROC solutions for the process industry offer long-lasting, maintenance-free and energy-efficient products

For more information read the following article

When planning a sustainable building, the main challenge is how to achieve eco-friendly goals while ensuring a safe and well-functioning structure. In terms of energy, efficiency, it is not a question of how much insulation to add, but what is the right application choice for the building, considering both the entire ecosystem-building and its function as a system, to achieve full owner satisfaction and occupants.

For more information click here!

When planning a sustainable building, the main challenge is how to achieve eco-friendly goals while ensuring a safe and well-functioning structure. In terms of energy, efficiency, it is not a question of how much insulation to add, but what is the right application choice for the building, considering both the entire ecosystem-building and its function as a system, to achieve full owner satisfaction and occupants.

Thinking in terms of design through the lens of integrated systems (so that the acoustic, thermal and humidity mitigation systems work fully and efficiently throughout the life of a building), which takes into account the physical interfaces between the facade and the the building structure, as well as the functional structure between the envelope and the systems, represents a salient point in eco-friendly design. The regulatory framework, in this context, has changed over the years, paying particular attention not only to the aspects of energy containment of buildings, but also to those related to acoustic well-being, sustainability and safety (with particular attention to the danger of propagation of fire).

The trend in recent years to build ever taller buildings has brought the increased fire risk to the building system to the attention of researchers. In fact, architects and designers of curtain walls have often recognized that the void created between the attic and the external wall, if left unprotected, would allow fire and smoke to spread quickly from one floor to another.

Firespan 40 & 90 EU panels offer a solution to this problem as they have been tested to the North American standard ASTM E2307: a fire test standard for evaluating the performance of perimeter fire barrier systems that measures the capability of perimeter fire barrier systems prevent the spread of fire when the outer wall flexes or deforms during exposure to fire. ASTM E2307 also determines the period of time in which the perimeter fire protection system limits the penetration of the flame through the cavity (internal void between the floor and the external wall.)

Firespan 40 & 90 EU are Underwriters Laboratories certified fire resistant panels, moisture resistant, which guarantees anti-corrosion and anti-mold effect, moreover they do not deteriorate over time, maintaining constant performance of thermal insulation, fire protection, better acoustic comfort and vapor barrier with the foil faced Firespan 40 & 90 or used in steel back pan assemblies. The panels comply with the North American standards ASTM C 612 and UL specific for mineral fiber panels.

Firespan 40 & 90 EU possess the certifications necessary for the buildings to obtain the LEED and are scrupulously examined at each stage of the life cycle in order to calculate their environmental impact

All related information is collected and published in technical documents and certificates called EPD (Environmental Product Declaration) in accordance with the EN 15804 standard.

For further information please do not hesitate to contact us!

Quality, innovation, safety and lightness solutions: these are just some of the values that characterize the world of sailing and that Link Industries searches every day in its work.

Inspired by these ideas we are proud to support, with our partner Paroc, Tommaso Cilli and Bruno Mantero at the 420 Italian Sailing Championship and on the occasion of the 420 Gold Cup.

Insulating materials can significantly increase the ability of a building to withstand a fire, consequently the choice of the correct insulator can affect the general safety of a building.

For more information read the following article.

How can the Process Industry contribute to reduce the negative climate impact - and at the same time save money? Fortunately, there is a simple solution to the problem: PAROC, focused on the characteristics of the industrial process, offer long-lasting, maintenance-free and energy-efficient solutions that can guarantee a specific industrial process with the lowest possible energy consumption, thus minimizing waste.

For more information read: PAROC solutions for insulation in the process industry

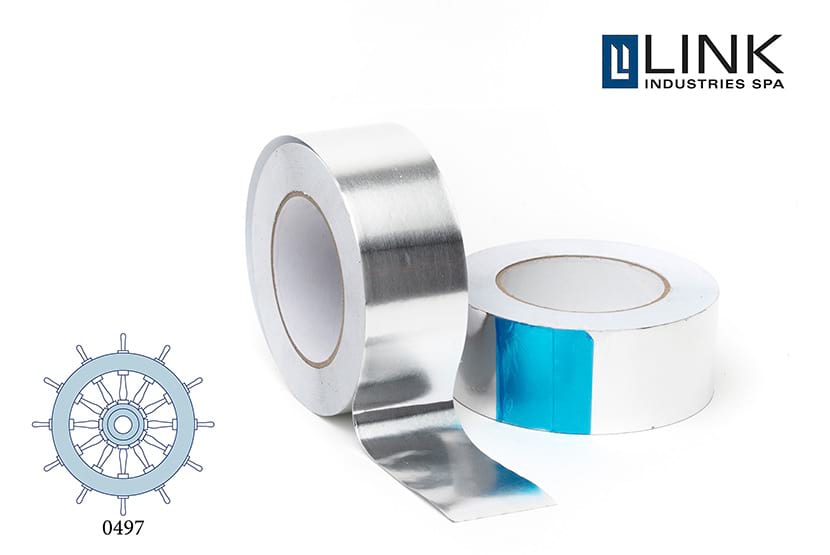

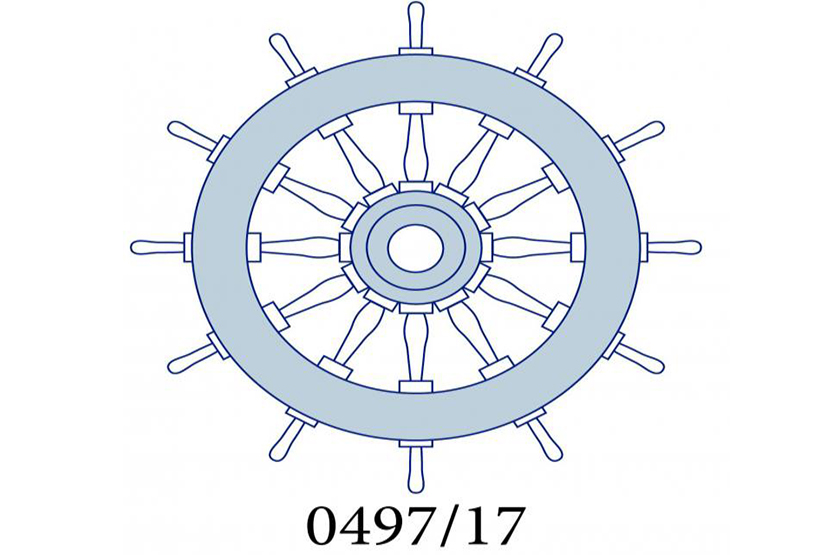

Thanks to the continuos research of our technical team, Link Alu Tape has obtained the marine equipment brand "Steering wheel" according to the Directive MED 2014/90 / UE.

Thanks to the continuos research of our technical team, Link Alu Tape has obtained the marine equipment brand "Steering wheel" according to the Directive MED 2014/90 / UE.

LINK ALU TAPE is a tape with smooth baked aluminum film in thickness 26 μm with high self-adhesive power. It is generally used for joints and other forms of protection in industrial, hvac and marine insulation. The tape has been rigorously tested by a third-party certifying body and has successfully passed the verifications thus obtaining the certification of "Low flame spread” for marine application.

By certifying its products (tapes for joints, glue, sealants) Link aims to:

- improve maritime safety;

- improve the protection of the maritime environment;

- facilitate the free exchange of marine equipment within the European Union and at the same time maintain a common level of security.

For more information read: Link Alu tape with 'timoncino' logo

Link presents PAROC Calculus on the market: an innovative and sophisticated software proposed by Paroc for the calculation of technical insulation. Calculus is an easy-to-use program suitable even for those who are not familiar with this type of software, that offers the possibility of creating your own database and saving the calculations of the entire project through two versions: on-line on the portal and a downloadable version one on the own pc with more features.

Link presents PAROC Calculus on the market: an innovative and sophisticated software proposed by Paroc for the calculation of technical insulation. Calculus is an easy-to-use program suitable even for those who are not familiar with this type of software, that offers the possibility of creating your own database and saving the calculations of the entire project through two versions: on-line on the portal and a downloadable version one on the own pc with more features.

The software calculates the solutions realized obtained with PAROC technical insulation products based on equations described in standard EN ISO 12241, which provides the methods for counting the properties related to the heat transport of building and industrial installations, mainly in steady state, providing a simplified approach to the treatment of thermal bridges. Furthermore, the latest developments of the program open the door to the world of shipbuilding: the database of available products has been updated by introducing the PAROC Marine & Offshore range, including all the relevant specialized coatings dedicated to them. This update allows to perform the calculations related to all the isolated insulated elements present on ships and offshore installations - such as drains, pipes, ducts, tanks - by correctly using the MED-certified PAROC products.

To perform calculations with Marine & Offshore products, just access the software link, place a check mark in the "Marine object" selection box under the "Select object" item. The offer of the product database goes on to naval ones.

tick the "Marine object" box under the "Select objet" heading. The product offering will be switched to marine products.

The introduction of Marine & Offshore products with specific coatings allows the correct thermal emissivity to be used in calculating the surface temperature of the insulation. This represents a considerable importance both for the protection of the embarked personnel, guaranteeing the effective safety of the material used, and for the guarantee of the correct functioning of the insulation applied. In fact modern shipbuilding increasingly pays attention on the issue of weight saving of boats for reasons of fuel efficiency, navigation autonomy and maneuverability. Moreover, a useful software, always updated and correctly configured on applied products by the parent company , is an indispensable tool for designers in order to assess the weight of the insulation used.

Calculus is free and easy to use with any device.

So all you have to do is try it and tell us your opinion!

The stone wool insulation is a natural product, used for over 80 years, obtained from molten volcanic rock, transformed in fibers and impregnated with a little bit organic binder (2-4%) in order to stabilize it, then passed into another oven for hardening and cutting to size.

The Paroc stone wool thus obtained is extremely natural and has excellent characteristics of: Durability - Energy efficiency - Sound absorption - Fire protection - Anti humidity - Reuse and Safety.

Paroc stone wool is not only a natural product, but naturally sustainable because it follows a precise protocol with respect for the environment: an added value for the environmentally conscious consumer who respects the resources of our planet.

For more information follow the link: Paroc the naturally sustainable insulation

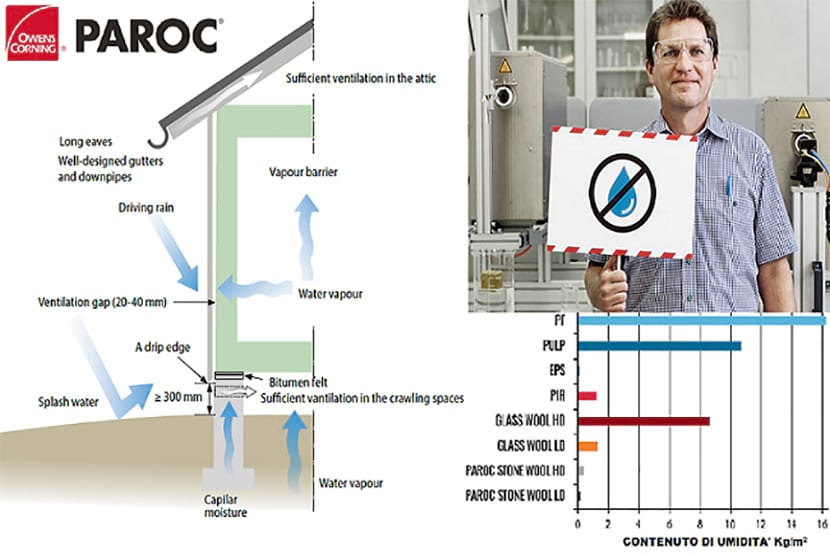

From an experimental study carried out on different insulating materials by an independent external laboratory, Paroc stone wool proved to be one of the most performing insulation materials in terms of moisture resistance. The analysis was carried out on four different mechanisms of moisture transport and their effect on buildings with the awareness that moisture penetrates the structures not only during atmospheric precipitation, but also through a silent path, difficult to control.

From an experimental study carried out on different insulating materials by an independent external laboratory, Paroc stone wool proved to be one of the most performing insulation materials in terms of moisture resistance. The analysis was carried out on four different mechanisms of moisture transport and their effect on buildings with the awareness that moisture penetrates the structures not only during atmospheric precipitation, but also through a silent path, difficult to control.

Moisture transport mechanisms are carefully studied in the building design phase, but they must also be carefully assessed during the construction of buildings, not only for the correct application of the products, but also for the interchanges between different materials and their conservation in the dockyard.

An independent study conducted by the VTT (VTT-S-05337-17) demonstrated that there are differences among the insulating materials in terms of moisture resistance.

In fact, during the construction of a building a certain amount of atmospheric water is inevitably given to the structure, in addition to the one contained in construction materials, and even if the insulation does not get wet, the humidity level of the rest of the components increases. For this reason, the water vapor permeability of the insulation materials plays a key role in the drying time of the entire structure, allowing moisture to escape.

For more information download the free Paroc Guide and follow the article on Edilportale: The driest insulation on the market

Heat dispersion, energy inefficiency, constructive discontinuities, reduced living comfort are some aspects that are felt in thermal bridge areas.

These areas, if not properly designed, cause various problems:

For more information: Link Industries: le zone di ponte termico e l'involucro edilizio

Modern construction can be defined not only by triumphs of contemporary architecture but also by ever-developing installation technologies. From heating and water pipes to smoke and exhaust pipes and chimneys, from HVAC equipment to ventilation ducts – installation systems perform many roles in terms of a building’s proper functionality; fire safety being one of the most important. Why should proper technical insulation be given priority when speaking about buildings’ passive fire protection?

For more information:

https://www.archiproducts.com/it/notizie/link-industries-e-una-questione-di-classe_66286

Designed for efficient air and water circulation for heating, ventilation and air conditioning purposes, HVAC systems often pass for a building’s “cardiovascular system”. Since it is common for pipework to cross through individual fire separation walls, it is crucial for them to retain sufficient fire protection. Because pipe penetrations weaken a partition’s overall resistance, professional fitting and proper materials are necessary in order to prevent/minimise fire transition through individual fire zones. Because of that all openings and service penetrations must meet certain requirements:

According to EN 1366-1 standard there are various types of ducts that differ in virtue of the propagation from inside or outside to the fire conduct (iào, ißo) and the vertical or horizontal arrangement of the pipeline ( I-I). When describing service penetrations’ fire resistance, we employ similar performance criteria as in the case of building components and construction, namely fire protection rating related to integrity (E) and insulation (I). Normally the fire resistance classification is given as a time limit (in minutes 15, 30, 45, 60, 90, 120, 180, 240 or 360) during which the performance criteria is fulfilled in a standardised fire test. Integrity (E) is the ability of a test specimen of a building construction element to prevent the flames and hot gases from passing through when exposed to fire on one side, and to prevent the occurrence of flames on the unexposed side. Insulation (I) defines said object’s ability to restrict the temperature rise of the unexposed face to below specified levels. Construction meets its integrity limit after ignition of a cotton wool pad or sustained 10 seconds’ flaming on the unexposed side. The limit for fire protection rating related to insulation (I) is met when the temperature increase on the unexposed side exceeds 180°C in relation to the initial state. The analogy between performance criteria between barrier walls and service penetrations is no coincidence. The latter, being part of fire separation walls, should be classified with fire protection classes (EI) required for said constructions, meaning a necessity to employ insulation materials with fire reaction class not lower than the fire resistance of the construction itself. Fume seal (S) defines the passage of flue gas to the side not exposed to fire.

Depending on the installation type, different insulation methods and materials should be applied and ventilation ducts must be selected with the appropriate fire-fighting performance. Paroc has developed a non-combustible wired mat usually covered with aluminum foil interposed between the wool and the net for fire protection of the ventilation ducts. The product is PAROC Hvac Fire Mat (Alucoat), a fireproof, flexible mattress made of biosoluble rock wool, covered with aluminum foil on one side and then quilted with a triple-twist hexagonal galvanized steel mesh. It is tested to achieve a protection up to EI 120 of rectangular and circular ducts, both vertical and horizontal, for internal and external fire exposure. For all the solutions, the product thicknesses to be applied and the characteristics of the metal pipelines will have to respond to what reported in the laboratory certificates.

At the time of installation it is required to cover the ventilation duct with the PAROC Hvac Fire Mat Alucoat mat and to close the longitudinal and transverse edges with galvanized steel wire. Fix the mat further to the ventilation duct with the galvanized steel wire every 330 mm (two fastenings per mattress band).

For more information:

https://www.archiproducts.com/it/notizie/link-industries-e-una-questione-di-classe_66286

Le Pipe Sections Paroc are on Infobuild news

The stakeholder’s primary interest is to ensure a functional, efficient and, of course, beneficial investment. With this aim, Link presents PAROC Pipe Sections, the suitable product to increase the efficiency and lifetime of industrial plants as well as to achieve a proper thermal insulation of high-temperature pipes or pipes for sanitary water heating, and to minimize energy consumption by maximizing the real life of the plant.

PAROC stone wool is a natural and environmentally friendly material that offers highly performing solutions for thermal, acoustic insulation and passive fire protection in civil engineering and upgrading, industrial plants, naval and off- shore.

In addition, the research and development activities in the industrial insulation has received advantage from close cooperation with customers and industry experts. All products are designed to increase the efficiency and functionality of the plant and to meet the strictest quality standards.

Therefore, we would like to introduce you, through the related product and video-related cards, the above-mentioned Pipe Sections:

Generally stone wool solutions and particularly PAROC Pipe Sections increase the comfort and safety of the environments in which they are used, improving the energy efficiency of buildings and yield performance of the plants: the advantages are of great economic value and environment resulting from a well-insulated system.

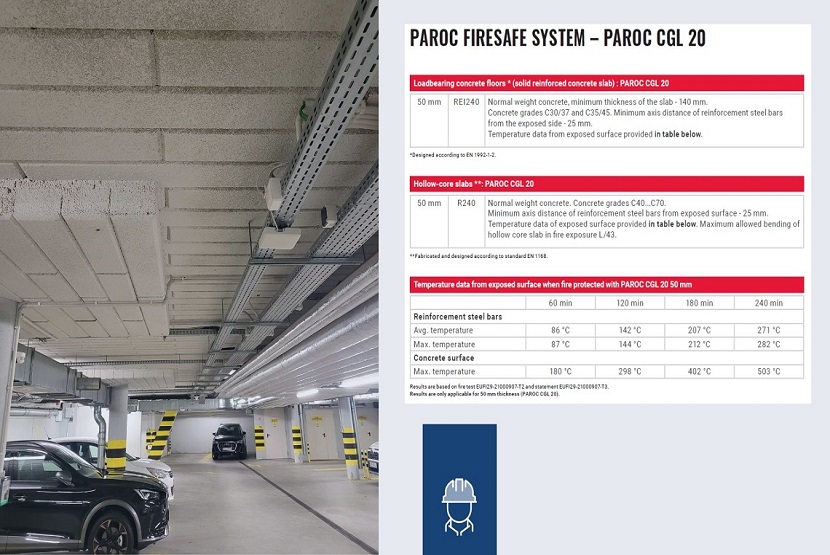

New tests for fire protection of steel and concrete with PAROC CGL20cy and PAROC FPS 17.

PAROC has developed two specific products for protection of concrete (PAROC CGL20cy and PAROC FPS 17) and steel (PAROC FPS 17) exploiting the excellent thermal-acoustic and fire protection properties of stone wool.

Concrete - PAROC CGL20cy protects until REI 240 with only 60mm of insulation on whatever type of concrete slab

Concrete and steel - PAROC FPS17 protects until REI 240 with only 20mm of insulation on whatever type of concrete slab and until R 210 whatever type of steal beams and pillars with several thicknesses.

For more information, send a email at isolamento@linkindustries.com

Link Industries Spa strongly believe in high quality products accompanied by relevant certifications as a main value for our customers.

Therefore the range of accessories for marine insulation offered by Link is covered by following certifications:

Module B - Low flame spread M.E.D. Certification according to IMO Res. Msc. 61(67) FTP Code Annex 1 p 2 and 5

Module E (EC quality System Certificate).

Link Industries Spa strongly believe in high quality products accompanied by relevant certifications as a main value for our customers.

Therefore the range of accessories for marine insulation offered by Link is covered by following certifications:

Module B - Low flame spread M.E.D. Certification according to IMO Res. Msc. 61(67) FTP Code Annex 1 p 2 and 5

Module E (EC quality System Certificate).

LINK GLASS FABRIC TAPE 0.12

White glass fabric strip 105 gr/m2 and 0.12mm with special self-extinguish resins to make it soft, permeable to glue and weavelock.

It is particularly indicated in marine application to cover joints between mineral wool slabs covered with glass fabric coating.

LINK GLUE V20

white flame retardant vinyl adhesive for marine application particularly indicated to bind glass fiber strips on joints between mineral wool slabs covered with glass coating.

For further information our technical department is at your constant disposal.

It is also used for gluing coatings (such as glass cloths) to insulating materials such as mineral wools (stone or glass wool)

LINK PE WRAP

Incombustible stone wool slab PAROC Marine Slab wrapped in a polyethylen self extinguish black film.

It is mainly used in marine application for the insulation of floor inside cabins.

For further information our technical department is at your constant disposal.

Sede Amministrativa: Ponte Morosini, 49 Marina Porto Antico 16126 Genova

ITALIA

Tel. +39 010 2546.901 – Fax +39 010 2546.999 –

Sede Logistica: Strada della Guasca, Zona Industriale D5 15122 Spinetta Marengo ITALIA

Tel. +39 0131 216.556 – Fax +39 0131 611.447

Cookie Policy